3D scanners deliver substantial convenience across various industries, from manufacturing and healthcare to art and heritage preservation. However, they are not a one-size-fits-all solution; their effectiveness can vary based on specific applications and contexts. This article will delve into what 3D scanners can and cannot do, providing readers with a deeper understanding of these innovative devices and guiding them in making informed decisions about their use. By examining real-world applications and challenges, we aim to highlight how 3D scanning technology can best serve diverse needs while recognizing its boundaries.

What can a 3D scanner do?

1. Capturing Complex Geometric Structures

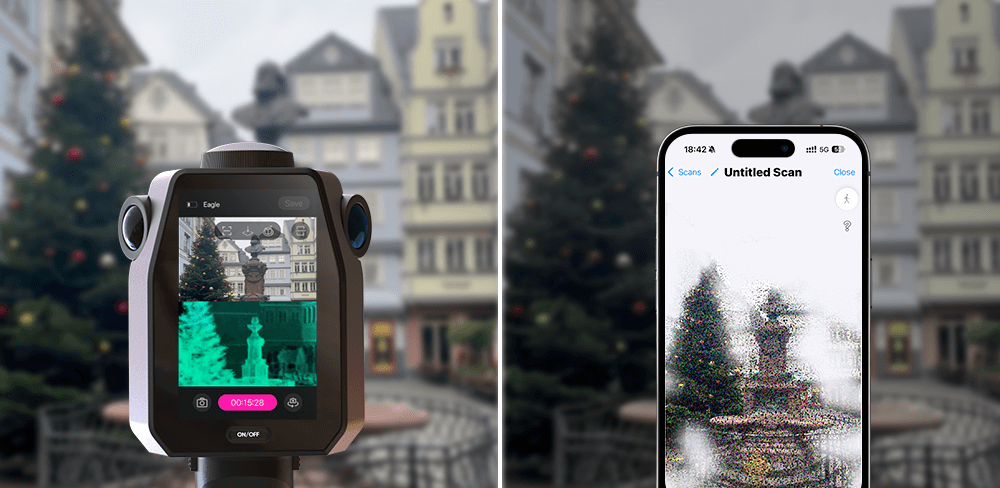

3D scanners excel at capturing intricate details and complex forms, making them indispensable tools in architecture, product design, and the arts. Their precise digital replication capabilities ensure that even the finest textures and characteristics of an object are preserved. Some models even offer color imaging for added realism.

Different scanners come with distinct advantages tailored to various applications. For instance, frame-encoded scanners are known for their speed, affordability, and user-friendliness, making them ideal for beginners. Phase-shift scanners perform exceptionally well in low-light conditions or when scanning dark or reflective surfaces, delivering outstanding precision. Meanwhile, LiDAR scanners specialize in mapping spaces and environments. By selecting the scanner that best suits their specific needs, users can maximize efficiency and effectiveness in their respective fields.

2. Creating Digital Models for Prototyping

In product development, 3D scanning technology significantly accelerates the prototyping process. Engineers and designers can swiftly scan existing objects, modify them in software, and generate new designs without starting from scratch. This rapid iteration not only saves time but also reduces costs, empowering teams to innovate more freely. For instance, in the automotive industry, designers can scan physical models to assess the aerodynamic performance of new components and make quick adjustments based on data-driven insights.

A variety of model editing software is available, enabling precise adjustments and modifications based on scan data. Users can hollow out models or add and remove specific sections, enhancing customization capabilities. Additional features, such as deep noise reduction and dimensional measurement, further improve the scanning quality. When paired with model editing software, a 3D scanner effectively functions as an equal to modeling software, streamlining the transition from concept to prototype.

3. Enabling Reverse Engineering

In industries like manufacturing, reverse engineering is essential for maintaining a competitive edge. 3D scanners empower businesses to create precise digital copies of old components, facilitating the replacement of outdated parts with modern equivalents. These digital replicas can be easily replicated or modified to meet contemporary standards, extending the lifecycle of essential components while minimizing reliance on costly original molds and tooling.

Additionally, 3D scanning significantly cuts costs and enhances operational efficiency. By streamlining the reverse engineering process, companies can accelerate product development, reduce errors, and optimize resource allocation. This technology not only revitalizes legacy parts but also paves the way for innovation, making it an invaluable asset in today's fast-paced manufacturing landscape.

4. Preserving Cultural Heritage

Museums and cultural institutions are leveraging 3D scanning technology to preserve artifacts and historical sites for future generations. By creating detailed digital records, these invaluable cultural treasures remain accessible for research and public display, even if the physical objects suffer damage over time. This technology also facilitates virtual tours of historical sites, enabling global audiences to experience them firsthand.

Artifacts can be scanned using structured light scanners, which capture the entirety of each piece non-invasively, with high precision and rich detail, thereby maintaining its integrity and uniqueness. For larger sites, radar spatial scanners can encompass vast areas and export data to VR glasses, providing an immersive cultural experience. Alternatively, this data can be showcased on online platforms, simulating an on-site visit for users.

5. Medical Applications

In healthcare, 3D scanning is revolutionizing patient care by enabling the creation of custom prosthetics and dental implants. These scanners accurately capture patients’ anatomical details, resulting in better-fitting solutions tailored to individual needs. This level of personalization enhances both comfort and functionality, significantly improving patients’ quality of life.

A variety of specialized medical scanners are now widely utilized, including intraoral scanners for custom dental molds and oral imaging; facial scanners for structural visualization, skin analysis, and cosmetic recommendations; cochlear scanners for personalized hearing aids; prosthetic scanners to aid in restoring mobility; and scoliosis scanners to ensure precise orthotic fitting. By embracing 3D scanning technology, the medical field is delivering more efficient and accurate solutions, ultimately providing patients with superior care and enhanced quality of life.

6.Commercial Applications

3D scanning is reshaping the commercial sector by introducing innovative solutions like virtual fitting rooms, which allow consumers to try on clothes and shoes from the comfort of their homes. This immersive shopping experience not only enhances customer satisfaction but also significantly helps businesses reduce return rates.

Moreover, products can be presented in stunning 3D on e-commerce platforms, offering a more engaging and interactive visualization than traditional 2D images. This dynamic representation enables customers to explore items from various angles and understand their features more thoroughly, fostering a more informed purchasing decision. By leveraging 3D scanning technology, retailers can create a more personalized shopping experience, drive sales, and strengthen their brand presence in a competitive marketplace.

7. Gaming Industry Applications

3D scanning is revolutionizing the gaming industry by optimizing game development tools and seamlessly integrating with virtual reality (VR) headsets. This technology allows developers to create highly detailed and realistic models and environments, enhancing the immersive experience for players. Additionally, consumers can scan their favorite collectibles, enabling DIY customization or replication, which adds a personal touch to their gaming experience.

However, as with any technological advancement, copyright issues must be carefully navigated to avoid infringement. While personal use and collection of scanned items are generally permissible, it is crucial for consumers to understand the legal implications associated with reproducing copyrighted materials. By addressing these concerns, the gaming industry can fully harness the potential of 3D scanning, offering innovative experiences while respecting intellectual property rights.

8. Applications in Education

As previously noted, 3D scanning technology generates detailed scan data that facilitates online viewing of 3D models, offering significant advantages across all sectors of society. For educators, this advancement enhances teaching methods by providing interactive and visually compelling materials that can bring complex concepts to life. For students, it boosts engagement and motivation, allowing for an immersive learning experience that appeals to diverse learning styles.

Moreover, for scholars and researchers, 3D scanning fosters greater collaboration by enabling the sharing of online resources and facilitating the exchange of experiences with colleagues across geographical boundaries. This collaborative environment promotes innovation and knowledge sharing, ultimately enriching the educational landscape.

What a 3D Scanner Cannot Do

a) Scan Transparent or Reflective Surfaces

One notable limitation of 3D scanners is their difficulty in accurately capturing transparent, highly reflective, or dark objects. For example, materials like glass, mirrors, and shiny metals can produce distorted scans due to light scattering and reflection, while dark surfaces may lead to scanning failures. To achieve viable results in such cases, additional treatments—such as applying a matte spray—might be necessary, complicating the scanning process. However, some advanced phase-shift scanners are designed to adapt to various light conditions and can effectively scan objects of different colors, overcoming some of these challenges.

b) Assessing Material Properties

While 3D scanners excel at capturing geometric details, they do not evaluate material properties such as weight, texture, or durability. A comprehensive understanding of an object’s performance necessitates complementary methods, including laboratory testing and analytical techniques that are crucial for engineering applications. These additional assessments are essential to ensure that materials meet the required specifications and performance standards.

c) Scaling to Large Objects

Most handheld or desktop 3D scanners are not suited for large-scale objects, such as buildings or extensive machinery. For these applications, specialized industrial scanners are required, which can be significantly more expensive and often necessitate specialized training. While these industrial solutions provide greater precision, they may not be practical for every project. Thus, careful consideration of the specific requirements and budget is essential when selecting the appropriate scanning technology for large-scale endeavors.

d) Instantly Creating Clean CAD Models

Most 3D scanners generate mesh files rather than editable CAD geometry. If you intend to use the scanned data for engineering or parametric design, you will need to convert it using specialized software. This conversion process is essential to ensure the model can be fully utilized in design applications, enabling precise modifications and enhancements.

e) Achieving Perfect Results

While 3D scanners can partially replace the 3D modeling process, achieving optimal scanning results still requires skill and knowledge. Think of yourself as the sculptor, with the scanner serving as a useful tool. It's essential to have a clear vision of your objectives, understand the entire scanning process, and know how to navigate challenges along the way to obtain the best possible results.

In the End

3D scanning has revolutionized various aspects of our lives, offering unprecedented convenience and efficiency. However, it is important to recognize that it is not a one-size-fits-all solution. This article is designed to provide you with valuable insights and practical knowledge, empowering you to navigate the nuances of 3D scanning technology. By equipping yourself with this information, you can make informed decisions and enhance your experience as you progress on your 3D scanning journey.