The application of 3D scanning in reverse engineering is transformative, offering significant advantages in accuracy, efficiency, and design flexibility. As industries continue to evolve and demand more innovative solutions, the role of 3D scanners will only become more critical. By enabling faster and more precise replication of existing products, this technology enhances the capacity for innovation and improvement, ultimately driving progress across various sectors.

Accuracy

One of the most significant advantages of 3D scanning in reverse engineering is the accuracy of data capture. Traditional methods of measurement often involve manual processes that can introduce errors, especially in complex geometries. In contrast, Lynx scanner has 0.10mm accuracy, creating a highly detailed digital model. This accuracy is essential for ensuring that the replicated product performs as intended, matching the original specifications.

Efficiency

Time efficiency is another critical benefit of utilizing 3D scanners. The speed at which data can be collected and processed drastically reduces the turnaround time for projects. In industries where time-to-market is crucial, the ability to quickly generate digital models means that teams can move from analysis to design and prototyping more swiftly. This efficiency not only enhances productivity but also allows for faster iterations and refinements in the design process. The Moose Scanner features a single capture range of 200x100 mm and incorporates AI Visual Tracking, allowing for seamless capture of the object's characteristics.

Flexibility

Furthermore, 3D scanning technology excels at handling complex geometries that might be challenging to measure manually. Many modern products feature intricate designs that require careful attention to detail. Mole 3D scanners can easily capture the nuances of these shapes, ensuring that every aspect of the object is represented in the digital model. This capability is particularly beneficial in fields like automotive and engineering, where precision is paramount.

Product Specification

0.10mm

0.03mm

0.05mm

0.30mm

0.07mm

0.1mm

10fps

10fps

10fps

Visual tracking

AI Visual tracking

Visual tracking

400-900mm

150-400mm

150-400mm

250x400mm

200x100mm

200x100mm

100-2000mm

15-1500mm

15-1500mm

NIR

Blue LED

NIR

Support

24-bit color textures

Extended support

244x75x48mm

115×70×35mm

141x80x80mm

800g

280g

390g

Success Story 1

Mastering the art of crafting tail lights with Lynx | 3DMakerpro Lynx

Success Story 2

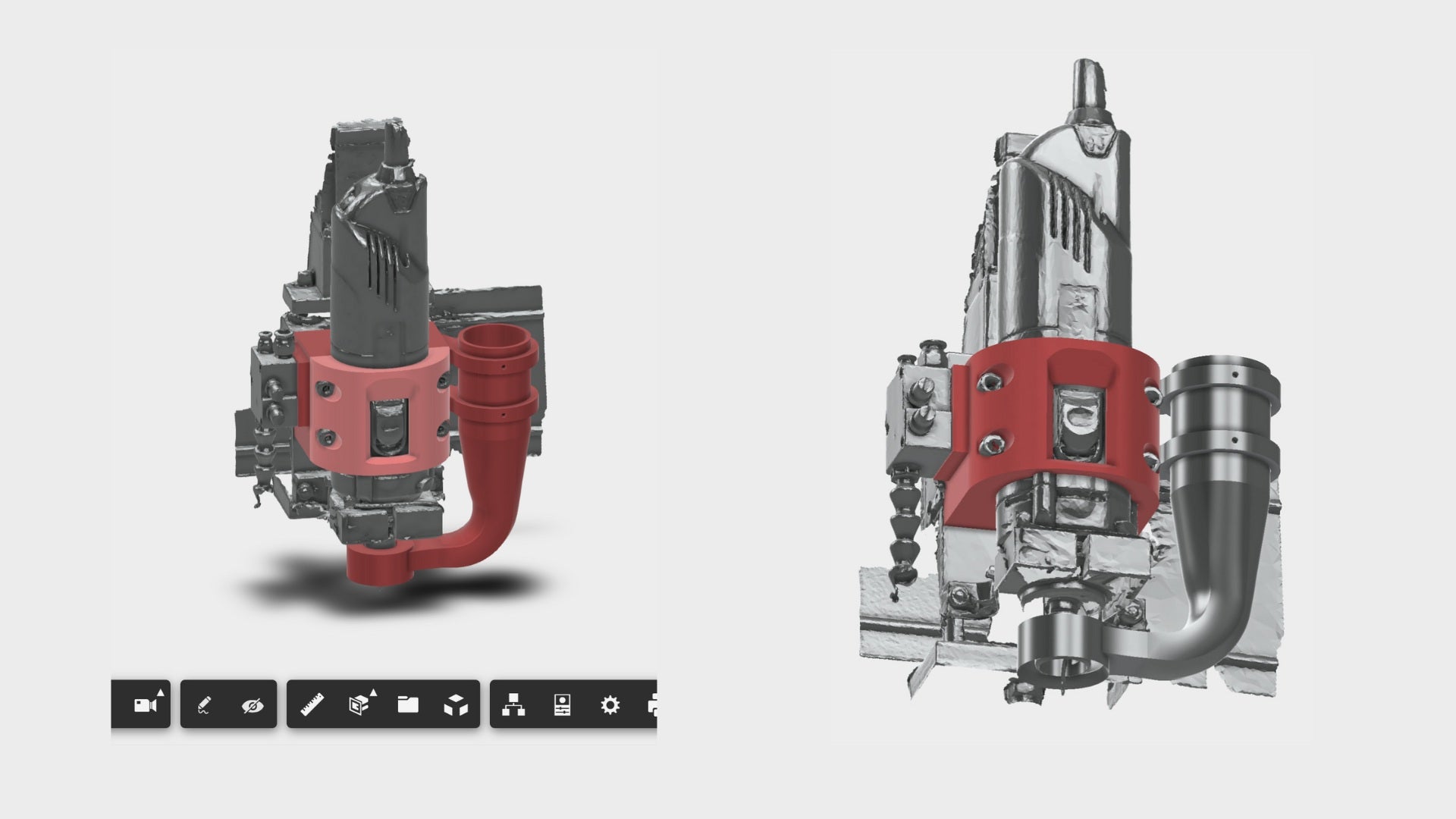

Kress CNC scanned with 3Dmakerpro Moose

Kress CNC scanned with 3Dmakerpro Moose and additional mounting bracket sketched in Fusion 360 and vacuum adapter sketched and lofted. Vacuum adapter is to get low volume High pressure shop vac as close as possible to the cutting action

Comming along now. just two brackets for the pipe and the loftet pipe to the suction nozzle. The upside is also that this mount stiffens the Z-axis in the X-axis due to the 5mm plate that the alumnium bracket is mounted to flexes abit.

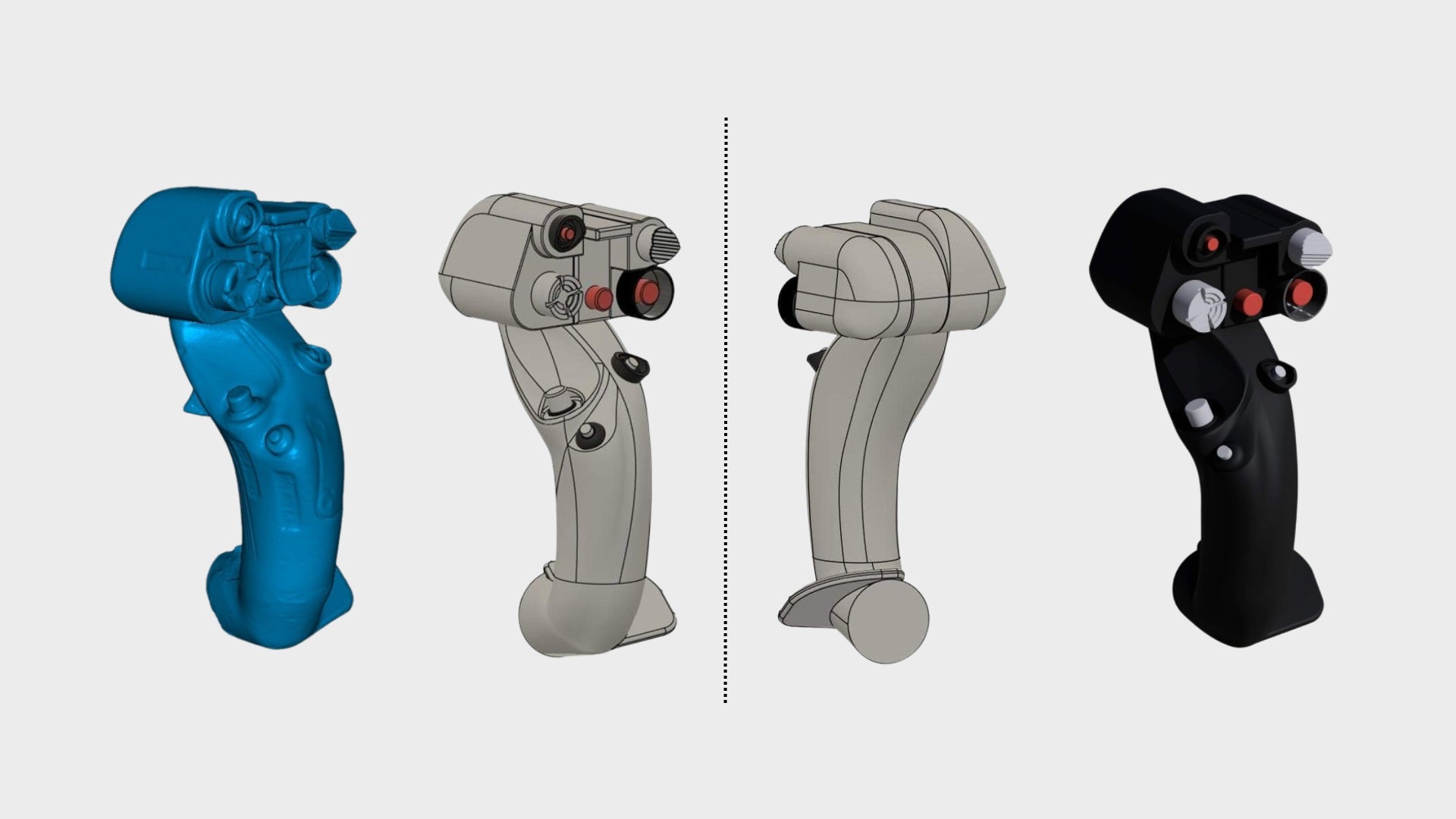

Success Story 3

Reverse engineering Flight controls by Moose Lite

Finally was able to use the Moose Lite for what I actually bought it for which was reverse engineering Flight controls for use in flight sims. Literally the perfect scanner for me as I didn't need extreme resolution(even though id argue that it looks amazing anyways) and it was a reasonable price. does make me wonder how the other more expensive 3d scanners compare to this or even the regular moose

Success Story 4

What can we do with 3D scanning and printing? |3DMakerPro Moose Scanner

Success Story 5

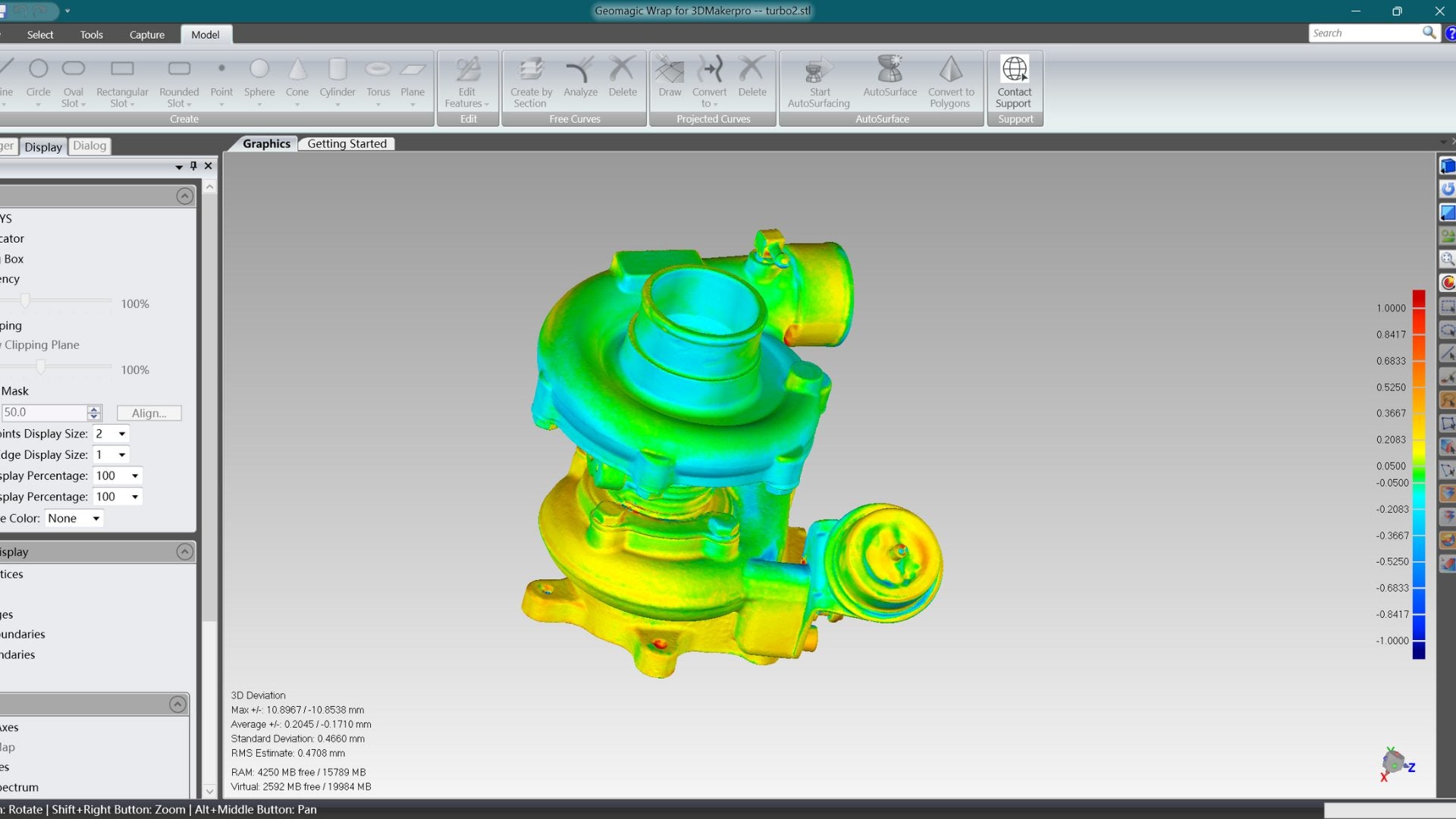

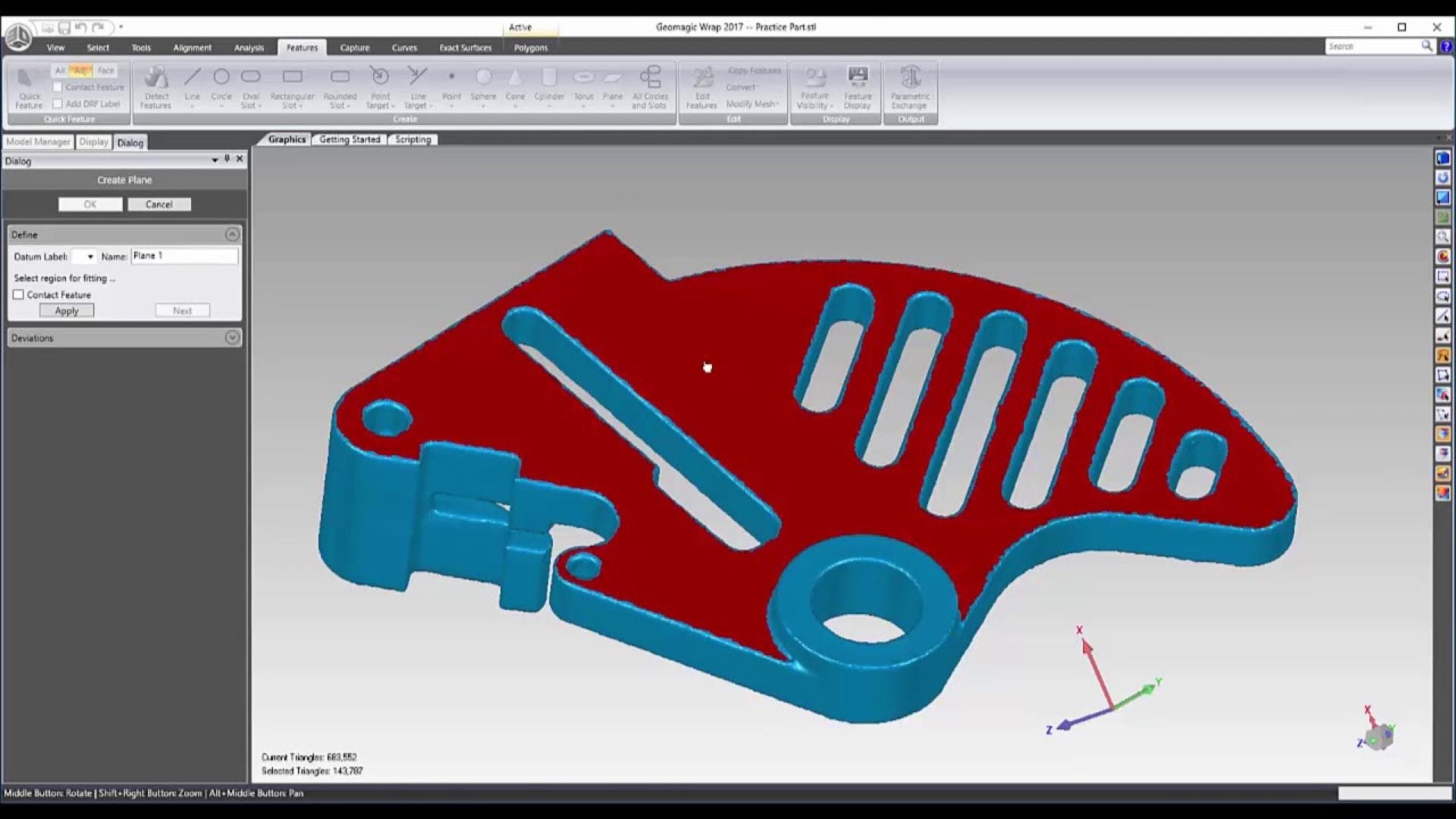

Geomagic Wrap - Reverse Engineering (Part 1)

Recommended Products