L'integrazione degli scanner 3D nella stampa 3D offre soluzioni robuste per duplicazione, modifica e riparazione oggetti in diversi settori. La loro capacità di creare rappresentazioni digitali accurate non solo migliora l'efficienza del processo di progettazione, ma promuove anche l'innovazione nello sviluppo dei prodotti. Con il progresso tecnologico, le applicazioni della scansione 3D continueranno ad espandersi, determinando ulteriori miglioramenti nelle capacità e nelle pratiche di stampa 3D.

Modelli 3D

Duplicazione

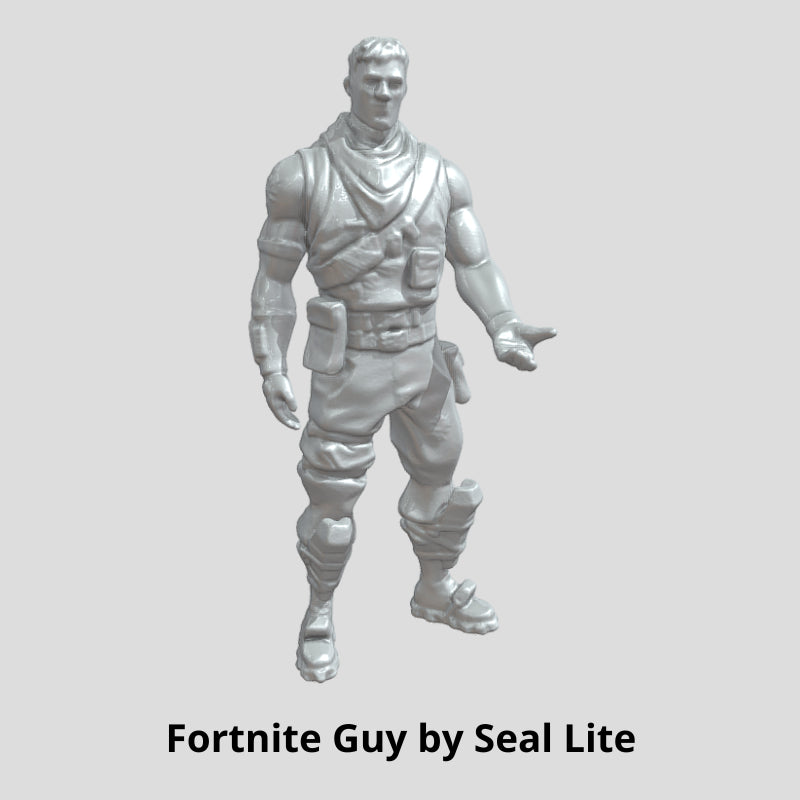

Una delle funzioni principali degli scanner 3D è quella di duplicare oggetti esistenti. Seal scanner, con il suo Precisione di 0,01 mm e lenti anti-vibrazione, raccoglie 100.000 punti al secondo, potenziando questa capacità. Ciò consente agli utenti di creare repliche digitali precise di oggetti fisici, che possono poi essere modificate o stampate direttamente. In settori come il restauro artistico, la conservazione del patrimonio culturale e la produzione manifatturiera, la duplicazione di oggetti garantisce il mantenimento di dettagli complessi e la riproduzione accurata dei progetti originali.

Seal Lo scanner 3D scansiona la Torre Eiffel delle Olimpiadi di Parigi!

Modifica e riparazione

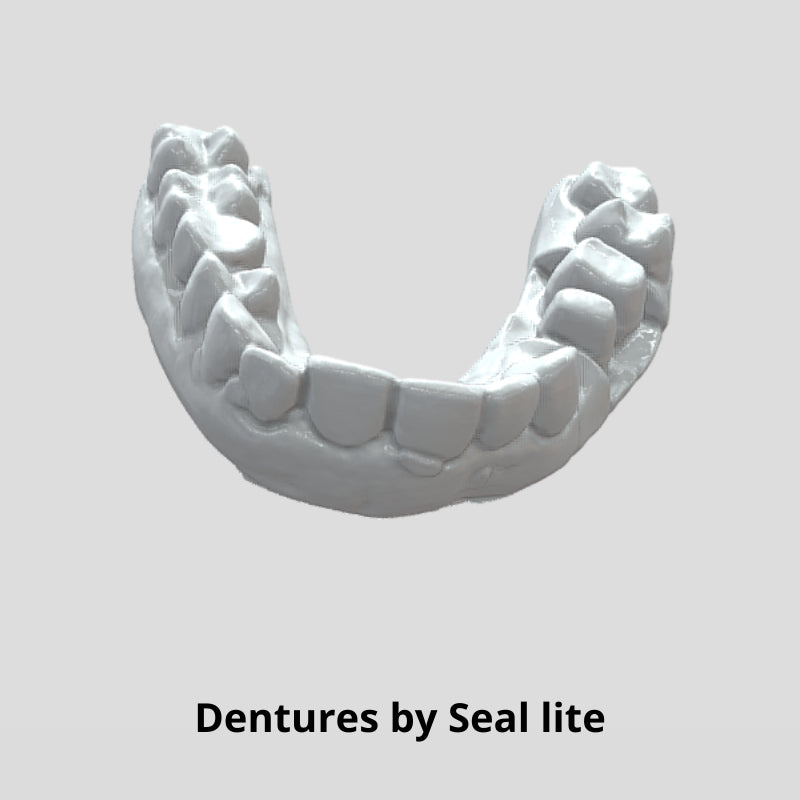

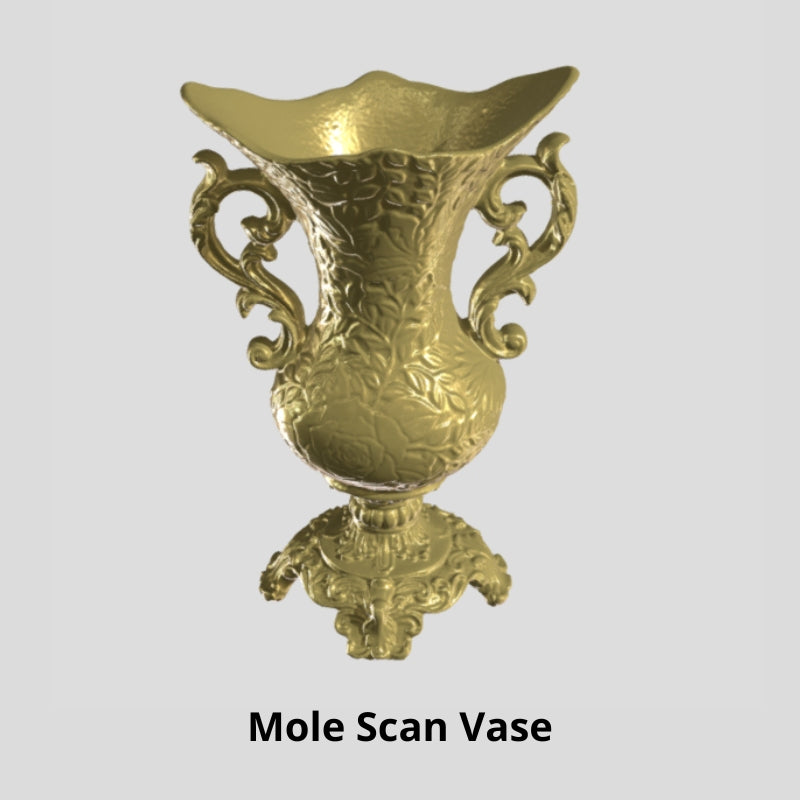

Oltre alla duplicazione, gli scanner 3D eccellono nella modifica e nella riparazione di progetti esistenti. Mole scanner Potere catturare oggetti che vanno di dimensioni da da 15 a 1500 mm e presenta una modalità texture ultra-chiara, con Precisione di 0,05 mm E Risoluzione di 0,1 mmQuando un oggetto scansionato viene importato in un software di modellazione 3D, può essere modificato per soddisfare requisiti specifici. Questo processo è particolarmente utile in settori come quello sanitario, dove dispositivi medici o protesi personalizzati possono essere adattati alle esigenze individuali. Inoltre, è possibile scansionare oggetti danneggiati, consentendo la progettazione e la stampa di riparazioni, prolungando così il ciclo di vita dei prodotti e riducendo gli sprechi. Questa adattabilità rende la scansione 3D un potente strumento per l'innovazione e l'efficienza.

Crea un pod a triplo calibro con il Mole Scanner 3D

Ampia applicazione

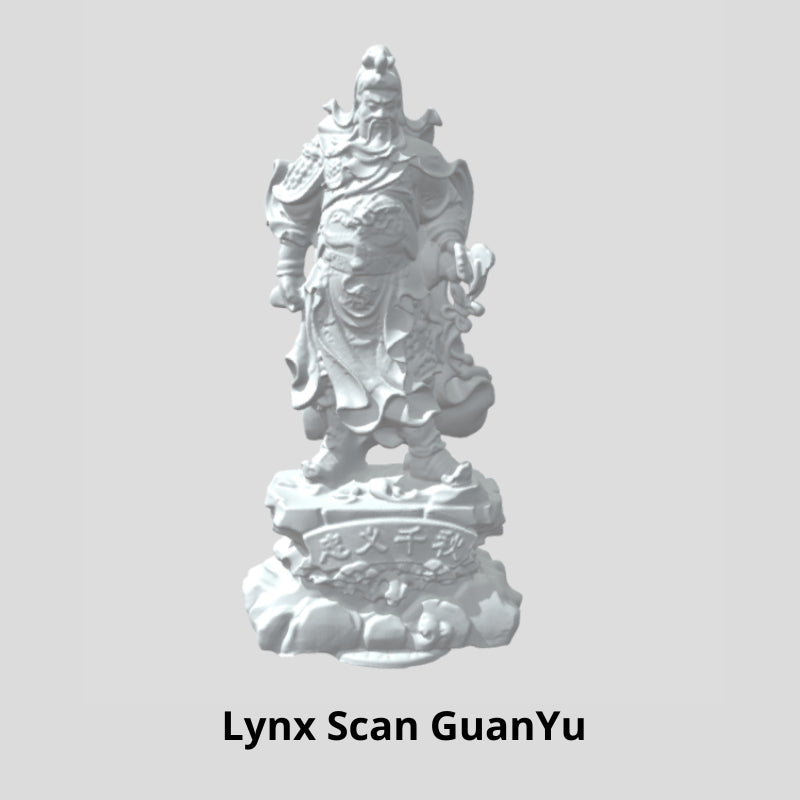

L'ampio campo di applicazione della scansione 3D ne sottolinea ulteriormente l'importanza nella stampa 3D. Questa tecnologia viene utilizzata in settori che vanno dall'automotive alla moda e all'architettura. Nel design automobilistico, ad esempio, gli scanner 3D possono catturare i dettagli più complessi dei componenti delle auto per la prototipazione e i test. Nella moda, gli stilisti possono creare capi personalizzati che si adattano perfettamente alle singole corporature. Inoltre, gli studi di architettura utilizzano la scansione 3D per creare modelli accurati di edifici per progetti di ristrutturazione, garantendo la perfetta integrazione dei nuovi progetti con le strutture esistenti. LynxLa portata di cattura singola è 250×400 mm, che è 200% più grande rispetto agli scanner tradizionali di medio formato. Con Lynx, puoi scansionare oggetti fino a 5000x5000x5000mm, un enorme Miglioramento del 3700%!

Scanner 3D di grande formato a meno di $ 400 - Scanner 3D 3D MAKER PRO LYNX

Confrontare

Specifiche di prodotto

Specifiche di prodotto

0,01mm

0,05 mm

0,10 mm

0,05 mm

0,1 millimetri

0,30 millimetri

10 fps

10 fps

10 fps

Tracciamento visivo

Tracciamento visivo

Tracciamento visivo

180-280 mm

150-400 millimetri

400-900 millimetri

100x75mm

200x100mm

250x400mm

10-300 mm

15-1500 mm

100-2000 millimetri

Luce blu

NIR

NIR

Supporto

Supporto esteso

Supporto esteso

110×60×35mm

141x80x80mm

244x75x48mm

254 g

390 g

800 g

Storia di successo 1

3DMakerpro Seal Scanner 3D - Unboxing

Storia di successo 2

3DMakerPro Mole Recensione dello scanner 3D: un ottimo scanner per oggetti di medie dimensioni

Storia di successo 3

3DMakerPro Lynx Unboxing e prima scansione

Intestazione

Consiglia prodotti

Usa questo testo per condividere informazioni sul tuo marchio con i tuoi clienti. Descrivi un prodotto, condividi annunci o accogli i clienti nel tuo negozio.

Seal Scanner 3D

Scanner 3D talpa