Content

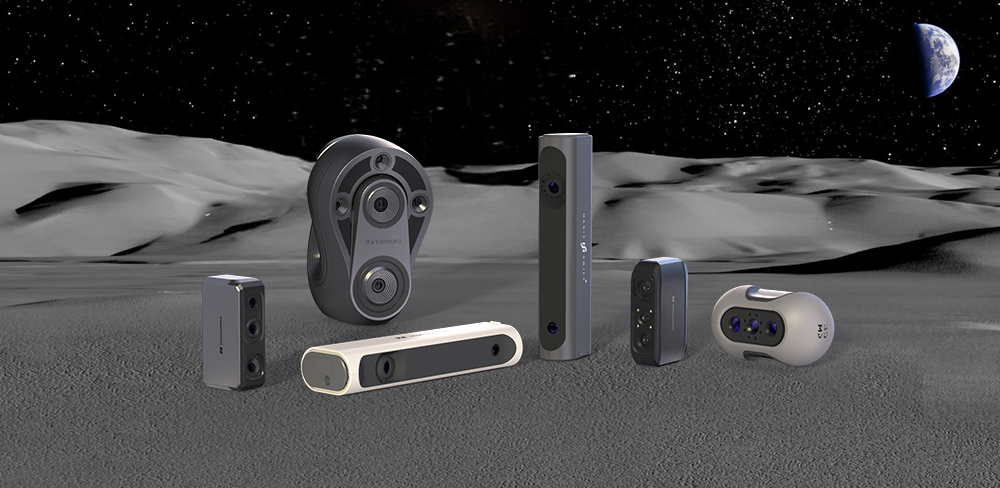

At 3DMakerpro, we're proud to support passionate innovators who are making a real difference in people's lives. One such ambassador is Imrich Molnár, whose recent project highlights the incredible potential of 3D scanning and printing in the field of prosthetics.

A Unique Challenge

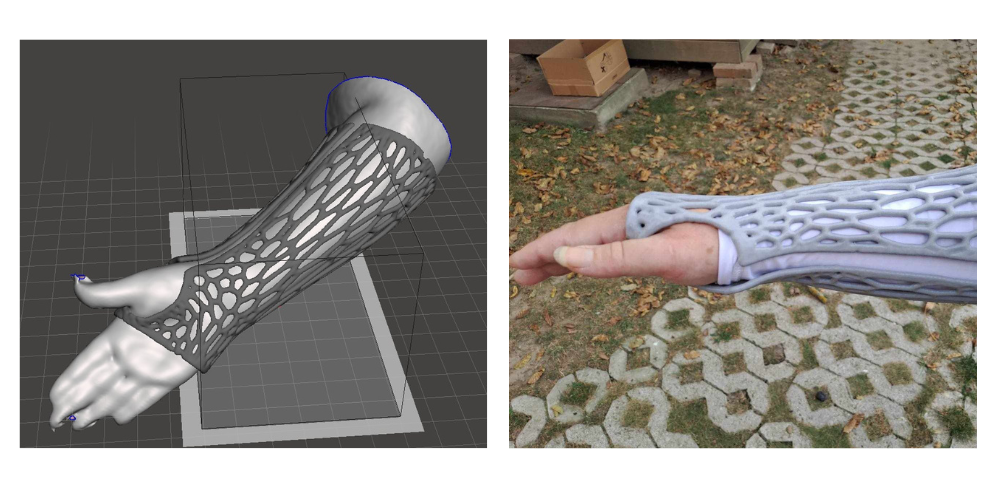

Imrich recently embarked on a special project to create a customized arm support for a friend in need. This wasn't just any project; it involved scanning the friend's arm, designing a lightweight, Voronoi-style support, and testing the final product—all with the help of our Mole 3D scanner. Imrich's dedication to using technology to enhance lives is truly inspiring.

The Scanning Process

Before starting the design process, Imrich meticulously researched the best practices for creating a prosthetic support. While many resources suggested using Rhinoceros with Grasshopper, he opted for a more accessible approach by utilizing Meshmixer's algorithmic solutions. With the Mole scanner, he was able to accurately capture the details of the arm, aligning the scans with precision. This ensured a solid foundation for the next steps.

Designing with Creativity

Once the scanning was complete, Imrich imported the model into Meshmixer, where he worked his magic. He cleaned up unnecessary elements, duplicated and offset the model, and experimented with polygon reduction to achieve the perfect balance between aesthetics and functionality. The result? A stunning Voronoi structure that was not only lightweight but also visually appealing.

Printing Perfection

With the design finalized, Imrich turned to Orcaslicer to prepare the file for printing. He oriented the model strategically and adjusted the bottom for optimal bed adhesion. Using his K1 Max printer, he chose PETG for its durability and flexibility—ideal for a prosthetic device. The printing process went smoothly, and after some minor adjustments to enhance comfort, the final product was ready for testing.

A Rewarding Experience

Testing the arm support with its owner was a pivotal moment for Imrich. Despite the unfortunate circumstances that necessitated this project, the satisfaction of creating something so personalized was deeply rewarding. The owner was thrilled with the result, showcasing how technology can truly change lives.

Looking Ahead

Imrich Molnár's journey is a testament to the impact of 3D scanning and printing in prosthetics. His innovative spirit and commitment to helping others reflect the values we cherish at 3DMakerpro. We are excited to see what he will create next and how our Mole 3D scanner will continue to play a role in transforming ideas into reality.

Stay tuned for more inspiring stories from our ambassadors, and remember: with the right tools, the possibilities are endless!

A Unique Challenge

Imrich recently embarked on a special project to create a customized arm support for a friend in need. This wasn't just any project; it involved scanning the friend's arm, designing a lightweight, Voronoi-style support, and testing the final product—all with the help of our Mole 3D scanner. Imrich's dedication to using technology to enhance lives is truly inspiring.

The Scanning Process

Before starting the design process, Imrich meticulously researched the best practices for creating a prosthetic support. While many resources suggested using Rhinoceros with Grasshopper, he opted for a more accessible approach by utilizing Meshmixer's algorithmic solutions. With the Mole scanner, he was able to accurately capture the details of the arm, aligning the scans with precision. This ensured a solid foundation for the next steps.

Designing with Creativity

Once the scanning was complete, Imrich imported the model into Meshmixer, where he worked his magic. He cleaned up unnecessary elements, duplicated and offset the model, and experimented with polygon reduction to achieve the perfect balance between aesthetics and functionality. The result? A stunning Voronoi structure that was not only lightweight but also visually appealing.

Printing Perfection

With the design finalized, Imrich turned to Orcaslicer to prepare the file for printing. He oriented the model strategically and adjusted the bottom for optimal bed adhesion. Using his K1 Max printer, he chose PETG for its durability and flexibility—ideal for a prosthetic device. The printing process went smoothly, and after some minor adjustments to enhance comfort, the final product was ready for testing.

A Rewarding Experience

Testing the arm support with its owner was a pivotal moment for Imrich. Despite the unfortunate circumstances that necessitated this project, the satisfaction of creating something so personalized was deeply rewarding. The owner was thrilled with the result, showcasing how technology can truly change lives.

Looking Ahead

Imrich Molnár's journey is a testament to the impact of 3D scanning and printing in prosthetics. His innovative spirit and commitment to helping others reflect the values we cherish at 3DMakerpro. We are excited to see what he will create next and how our Mole 3D scanner will continue to play a role in transforming ideas into reality.

Stay tuned for more inspiring stories from our ambassadors, and remember: with the right tools, the possibilities are endless!

Featured collection

Medium-format

Save $292.00