Structured light 3D scanners are innovative tools that leverage light patterns to capture the three-dimensional shape of objects. This technology has revolutionized industries such as manufacturing, healthcare, and cultural heritage preservation. In this blog post, we'll explore the distinct working modes of structured light scanners, their advantages, and the diverse applications they serve.

Working Modes of Structured Light 3D Scanners

Structured light scanning can be categorized into several modes, each employing unique techniques to capture intricate 3D images. The primary methods include single-frame encoding, phase shift, speckle, and multi-line laser.

1. Single-Frame Encoding

a) Working Mode:

Single-frame encoding 3D scanners project a structured light pattern, typically stripes, onto an object and capture the deformed pattern in a single frame. This technology enables rapid scanning, typically completing a scan within 30 seconds to several minutes. With a scanning range of 10 to 3000mm and accuracy within 1 to 2 mm, these scanners are ideal for detailed inspections. Priced between $300 and $10,000, single-frame encoding scanners provide an accessible solution for businesses seeking efficiency and precision, significantly enhancing productivity in manufacturing and quality control applications.

a) Advantages:

One of the most significant benefits of single-frame encoding is its speed; because it captures all the information in a single snapshot, this method is ideal for applications requiring rapid data collection. This quick turnaround can significantly enhance productivity, particularly in manufacturing settings where time efficiency is crucial. Additionally, the simplicity of the setup, which requires fewer components than many other methods, can lower costs and streamline workflows.

c) Applicability:

In manufacturing, these scanners play a crucial role in quality control, swiftly verifying dimensions to maintain high standards and catch defects early in production. They are particularly effective for measuring small, intricate objects, making them invaluable in sectors like jewelry and electronics. Additionally, single-frame encoding scanners facilitate reverse engineering in automotive and aerospace applications by accurately capturing existing components for redesign. Their non-invasive nature also supports the documentation and preservation of cultural artifacts. Overall, the combination of speed, precision, and adaptability reinforces the significance of single-frame encoding scanners in driving innovation and ensuring quality across diverse fields.

2. Phase Shift

a) Working Mode:

Phase-shift structured light 3D scanners utilize a sophisticated working mode that projects a series of sinusoidal light patterns onto an object, capturing multiple images as the phase of these patterns shifts. Each image corresponds to a different phase, allowing the scanner to analyze the deformation of the projected patterns on the object's surface. By measuring these phase differences, the system calculates precise depth information, creating an accurate 3D model. Scans typically take between 10 and 60 seconds and can effectively operate within a range of 100 mm to 2000 mm. The accuracy of this method is often around 0.1 mm, making it ideal for applications requiring fine detail, such as medical imaging and component inspections. Although phase-shift scanners are priced between $10,000 and $40,000, their enhanced precision and reliability justify the investment for industries focused on high-quality outputs.

b) Advantages:

Phase-shift 3D scanners offer significant advantages that enhance their utility across various applications, primarily due to their precision and light adaptation capabilities. With an accuracy often around 0.1 mm, these scanners capture highly detailed measurements critical in fields like medical imaging and precision manufacturing, where even minor tolerances matter. Their robustness against ambient light conditions ensures reliable performance in diverse environments, eliminating the need for specialized lighting setups and making them suitable for outdoor scanning and varied factory settings. This adaptability guarantees consistent data quality despite fluctuations in external lighting. Additionally, their ability to capture intricate surface details makes phase-shift scanners ideal for complex geometries in industries such as aerospace and art conservation.

c) Applications:

In medical imaging, they facilitate the creation of detailed anatomical models for precise surgical planning and custom prosthetics. In manufacturing, their high accuracy enhances quality control, allowing for the early detection of defects and improving product reliability. The aerospace and automotive sectors benefit from their ability to capture complex geometries critical for structural analysis and safety compliance. Additionally, in cultural heritage preservation, these scanners aid in accurately documenting artifacts and historical sites, while in robotics, they improve object recognition and spatial awareness. Overall, the blend of precision, adaptability to different lighting conditions, and capability to capture intricate details ensures that phase-shift 3D scanners remain essential across diverse fields.

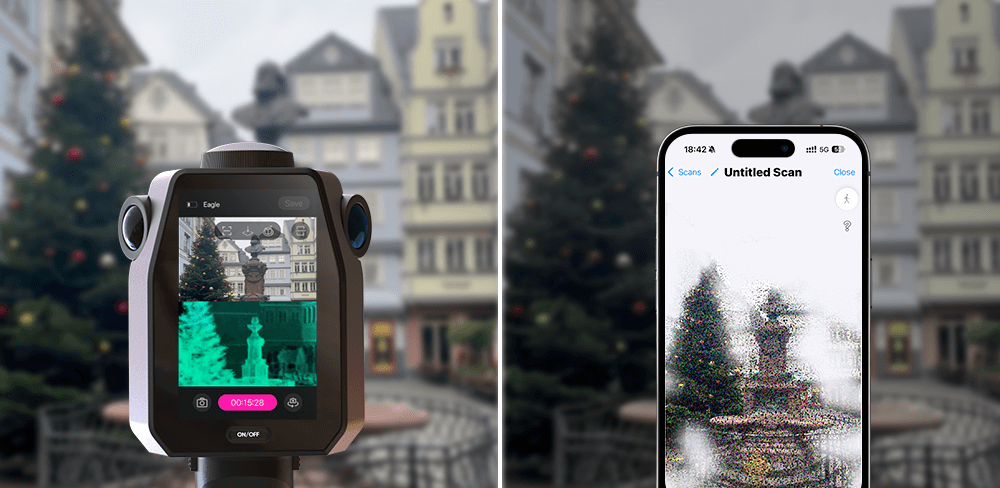

3. Speckle

a) Working Mode:

Speckle 3D scanners use a unique principle by projecting a random speckle pattern onto an object's surface to capture its geometry. A laser generates the speckle pattern, which deforms as it interacts with the object. A camera rapidly captures this distorted pattern and achieves throughput rates of up to 600 scans per hour. Advanced algorithms then analyze the images to extract depth information and create accurate 3D models. This structured light technology is essential for quality control, reverse engineering, and digital archiving across various industries. Priced between $10,000 and $50,000, speckle scanners offer high efficiency and accuracy, often achieving resolutions around 0.5 mm, making them a valuable investment for enhancing productivity and quality assurance in manufacturing.

b) Advantages:

The Speckle 3D scanner excels at capturing intricate details and delivers enhanced precision even with increasingly complex models, faithfully reproducing the original appearance of objects. Its exceptional low-light performance enables effortless scanning of dark-colored items without the need for specialized lighting, significantly broadening its range of applications. The non-intrusive measurement technology ensures that the structural integrity of delicate items is preserved. In summary, the seamless integration of speed, precision, improved accuracy for complex shapes, and high-efficiency performance in low-light environments makes the Speckle 3D scanner indispensable for enhancing productivity and product quality across various industries.

c) Applications:

Speckle 3D scanners are extensively used in manufacturing and quality control for inspecting component dimensions, as well as in the automotive sector for reverse engineering complex parts. In cultural heritage preservation, these scanners aid in accurately digitizing artifacts and historical sites for restoration and research. In architecture, they facilitate precise site surveys for existing structures. Additionally, speckle scanners play a vital role in consumer product design and in creating realistic 3D models for gaming and animation. Overall, the adaptability and precision of speckle 3D scanners significantly enhance productivity and quality across diverse fields, solidifying their importance in modern applications.

4. Multi-Line Laser

a) Working Mode:

Multi-line laser scanners employ a sophisticated imaging principle that projects multiple laser lines onto an object's surface to capture accurate three-dimensional data. They emit a grid of laser lines that deform based on the object's contours, while a camera rapidly captures images of the reflected lines, enabling simultaneous data collection. These structured light scanners can achieve speeds of up to 1,000,000 points per second, covering ranges from approximately 50 mm to 5 meters, with resolutions as fine as 0.1 mm. Priced between $10,000 and $80,000, multi-line laser scanners deliver both speed and precision, making them ideal for applications in manufacturing, construction, and cultural heritage preservation, where accurate measurements are crucial.

b) Advantages:

Capable of processing up to 1,000,000 points per second, Multi-Line Laser scanners ensure rapid data acquisition, which is vital in time-sensitive environments such as manufacturing and construction. With resolutions as fine as 0.1 mm, they provide the precision necessary for detailed measurements in quality control and reverse engineering. Additionally, their effective scanning range of approximately 50 mm to 5 meters allows for the capture of diverse object sizes and complexities. Overall, this combination of speed, accuracy, and versatility makes multi-line laser scanners invaluable tools for meeting the demanding requirements of modern industrial and research applications.

c) Applications:

In manufacturing, they are used for quality control to ensure component dimensions meet specifications, while in the aerospace and automotive industries, they facilitate reverse engineering and safety inspections. In construction and civil engineering, these structured light scanners support accurate site surveys and measurements of existing structures, aiding project planning. They also play a crucial role in cultural heritage preservation by digitizing artifacts and historical sites for documentation and restoration efforts.

Contrast Chart

| Feature | Single-Frame Encoding | Phase Shift | Speckle | Multi-Line Laser |

| Ambient Light Sensitivity | Low; requires controlled lighting | Moderate; performs well in various light conditions | High; effective in low-light | Low; optimized for controlled environments |

| Objects Surface | Smooth, well-defined surfaces | Various surface types, moderate texture | Rough and dark surfaces | Smooth surfaces |

| Scanning Speed | 20,000-300,000 Points / S | 100,000-1,000,000 Points / S | 300,000-600,000 Points / S | Up to 1,000,000 Points / S |

| Accuracy | 1-2 mm | ~0.1 mm | ~0.5 mm | ~0.1 mm |

| Scanning Range | 10-3,000 mm | 100-2,000 mm | 100-3,000mm | 50-5,000mm |

| Level of Difficulty | Easy | Moderate | Moderate to difficult | Moderate |

| Typical Price | $300 - $10,000 | $1,000 - $40,000 | $10,000 - $50,000 | $10,000 - $80,000 |

| Applications | Quality control, reverse engineering, cultural preservation | Medical imaging, component inspections, art conservation | Manufacturing, quality control, digital archiving | Manufacturing, construction, cultural heritage preservation |

Structured light 3D scanners have significantly altered the way we capture and interpret our environment, providing precise and efficient solutions for various industries. Each scanner type—single-frame encoding, phase shift, speckle, and multi-line laser—offers unique strengths and enriches the overall experience. From enhancing manufacturing quality control to preserving cultural heritage, these innovative tools not only increase accuracy and productivity but also inspire creativity. We hope that structured light scanners will bring exciting new colors to your 3D scanning journey.