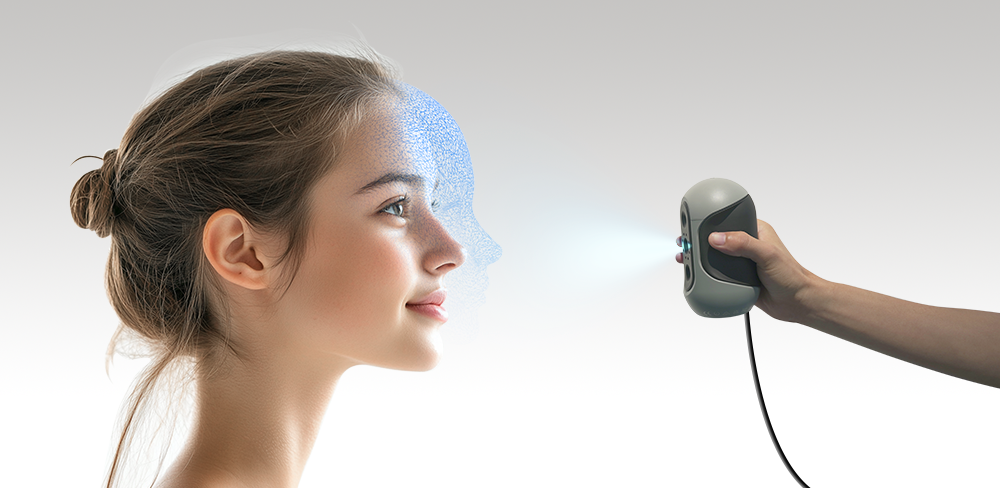

De wereld van muziekinstrumenten is net zo divers als de muzikanten die ze bespelen. Van snaarinstrumenten zoals violen en gitaren tot blaasinstrumenten zoals fluiten en trompetten, elk type heeft zijn eigen unieke kenmerken en eisen. Met de komst van 3D-scantechnologie, met name de innovatieve Mole Met een 3D-scanner heeft de personalisatie van deze instrumenten een nieuw niveau bereikt, wat een op maat gemaakte ervaring mogelijk maakt die voldoet aan de specifieke behoeften van elke muzikant. In deze blog onderzoeken we hoe 3D-scanners, met name de Mole 3D-scanner, kan verschillende soorten muziekinstrumenten aanpassen, de voordelen van deze technologie en wat het betekent voor muzikanten.

De veelzijdigheid van 3D-scannen in de instrumentenbouw 3D-scantechnologie maakt gebruik van lasers of gestructureerd licht om de precieze afmetingen en details van fysieke objecten vast te leggen, waardoor digitale modellen ontstaan die kunnen worden gemanipuleerd voor ontwerpdoeleinden. Mole 3D-scanneris, met zijn opmerkelijke nauwkeurigheid van 0,05 mm en resolutie van 0,1 mm, een onmisbaar hulpmiddel bij het personaliseren van een breed scala aan muziekinstrumenten.

1. Snaarinstrumenten

Gitaren en basgitaren

Voor strijkers zijn het gevoel en de klank van een instrument van het grootste belang. Mole 3D-scanner stelt gitaarbouwers in staat de exacte specificaties van het favoriete instrument van een muzikant vast te leggen, waardoor ze het met ongeëvenaarde precisie kunnen namaken of aanpassen. Of het nu gaat om het aanpassen van het halsprofiel voor comfort of het finetunen van de bodyvorm om de akoestiek te verbeteren, de verzamelde gedetailleerde gegevens kunnen leiden tot perfect op maat gemaakte gitaren en bassen. Houd er rekening mee dat de snaren moeilijk te herkennen zijn door de scanner omdat ze zo dun en bijna transparant zijn.

Violen en cello's

In de wereld van de klassieke muziek is het vakmanschap van violen en cello's vaak doordrenkt van traditie. Mole Met een 3D-scanner is het mogelijk om historische instrumenten te repliceren of nieuwe ontwerpen te creëren die de klankkwaliteit van klassieke meesterwerken behouden. Door een bestaand instrument te scannen, kunnen makers de kenmerken ervan analyseren en repliceren met moderne materialen, waardoor zowel authenticiteit als innovatie worden gegarandeerd.

2. Blaasinstrumenten

Koperblaasinstrumenten

Voor koperblazers kunnen de pasvorm en het gewicht van een instrument de uitvoering aanzienlijk beïnvloeden. Mole 3D-scanner Kan helpen bij het creëren van mondstukken op maat, afgestemd op de voorkeuren van individuele spelers, wat het comfort en de geluidsproductie verbetert. Bovendien zorgen de optische anti-shake modules en visuele trackingalgoritmen van de scanner voor een compleet en nauwkeurig model, waardoor aanpassingen in het bodyontwerp van trompetten of trombones mogelijk zijn voor een betere resonantie en bespeelbaarheid.

Houtblazers

De aanpassingsmogelijkheden voor houtblaasinstrumenten, zoals fluiten en klarinetten, zijn eveneens indrukwekkend. De MoleDe uitstekende optische compatibiliteit van de gitaren, zelfs met zwarte objecten, maakt nauwkeurige plaatsing van toongaten en aanpassingen aan de boring mogelijk, wat de geluidskwaliteit aanzienlijk kan beïnvloeden. Deze mate van maatwerk zorgt ervoor dat muzikanten de gewenste klankeigenschappen en bespeelbaarheid kunnen bereiken. Sommige muziekinstrumenten kunnen reflecterend overkomen, maar maak je geen zorgen, de Mole De scanner kan licht reflecterende items scannen. Als de reflectie sterker is, is scanspray nodig. Zie een andere blog -- 7 tips voor het scannen van reflecterende objecten voor gedetailleerde stappen en voorzorgsmaatregelen.

3. Percussie-instrumenten

Drums en malletinstrumenten

Percussionisten zoeken vaak naar instrumenten die specifieke tonen en volumes produceren. Met de Mole 3D-scannerDrumketels kunnen worden ontworpen om optimale geluidsresonantie te bereiken. Het compacte en ergonomische ontwerp van de scanner maakt hem gemakkelijk te gebruiken in zowel handheld- als draaitafelmodus, wat de creatie van malletinstrumenten zoals marimba's en xylofoons vergemakkelijkt, waarbij de afmetingen van de staven kunnen worden aangepast om specifieke toonhoogtes en klankkleuren te produceren.

4. Voordelen van maatwerk via 3D-scannen

A) Verbeterde prestaties

Op maat gemaakte instrumenten dragen bij aan een verbeterde bespeelbaarheid en comfort, waardoor muzikanten optimaal kunnen presteren. Door instrumenten aan te passen aan individuele specificaties, kunnen muzikanten zich concentreren op hun muziek zonder afleiding door ongemak of slecht passende apparatuur.

B) Unieke esthetiek

3D-scannen maakt niet alleen functionele personalisatie mogelijk, maar ook creatieve expressie. Muzikanten kunnen samenwerken met makers om instrumenten te ontwerpen die hun persoonlijke stijl weerspiegelen, met unieke vormen, kleuren en materialen. Deze artistieke vrijheid leidt tot unieke instrumenten die zowel visueel als akoestisch opvallen.

C) Efficiënte productie

De mogelijkheden voor snelle prototyping die mogelijk worden gemaakt door de Mole 3D-scanners stroomlijnen het ontwerpproces. Zodra een digitaal model is gemaakt, Geomagic Wrap voor 3DMakerpro software kunnen eenvoudig worden aangepast en getest, waardoor de productietijd van een definitief instrument aanzienlijk wordt verkort.

5. De toekomst van op maat gemaakte muziekinstrumenten

Naarmate de 3D-scantechnologie zich verder ontwikkelt, vooral met hulpmiddelen zoals de Mole Met de 3D-scanner zal de mogelijkheid tot personalisatie alleen maar toenemen. Opkomende trends zoals augmented reality (AR) kunnen muzikanten in staat stellen hun eigen ontwerpen te visualiseren vóór de productie, waardoor het proces nog interactiever en aantrekkelijker wordt. Bovendien zorgt de toegenomen toegankelijkheid van 3D-printen ervoor dat kleinere werkplaatsen hoogwaardige, op maat gemaakte instrumenten kunnen aanbieden tegen concurrerende prijzen.

Conclusie

De Mole 3D-scanner revolutioneert de manier waarop muziekinstrumenten op maat worden geproduceerd en biedt ongeëvenaarde mogelijkheden voor personalisatie en innovatie. Of je nu een professionele muzikant bent of een enthousiaste hobbyist, de mogelijkheid om instrumenten aan te passen aan specifieke voorkeuren transformeert de muziekervaring. Naarmate de technologie zich blijft ontwikkelen, belooft de toekomst van muziekinstrumenten op maat spannender en persoonlijker te zijn dan ooit, met de Mole 3D-scanners nemen het voortouw in dit nieuwe tijdperk van instrumentpersonalisatie.