Modello 3D

Usa questo testo per condividere informazioni sul tuo marchio con i tuoi clienti. Descrivi un prodotto, condividi annunci o accogli i clienti nel tuo negozio.

Ricambi auto di 3DMakerpro SU Sketchfab

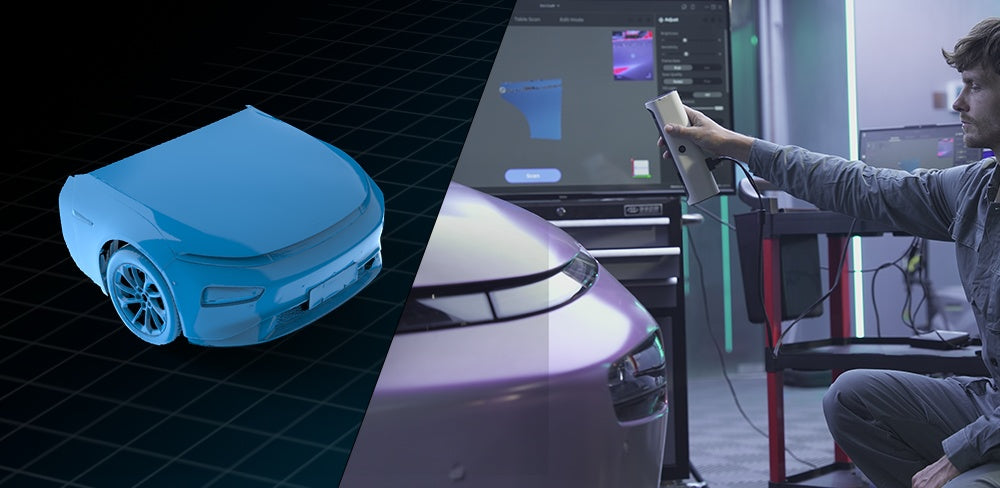

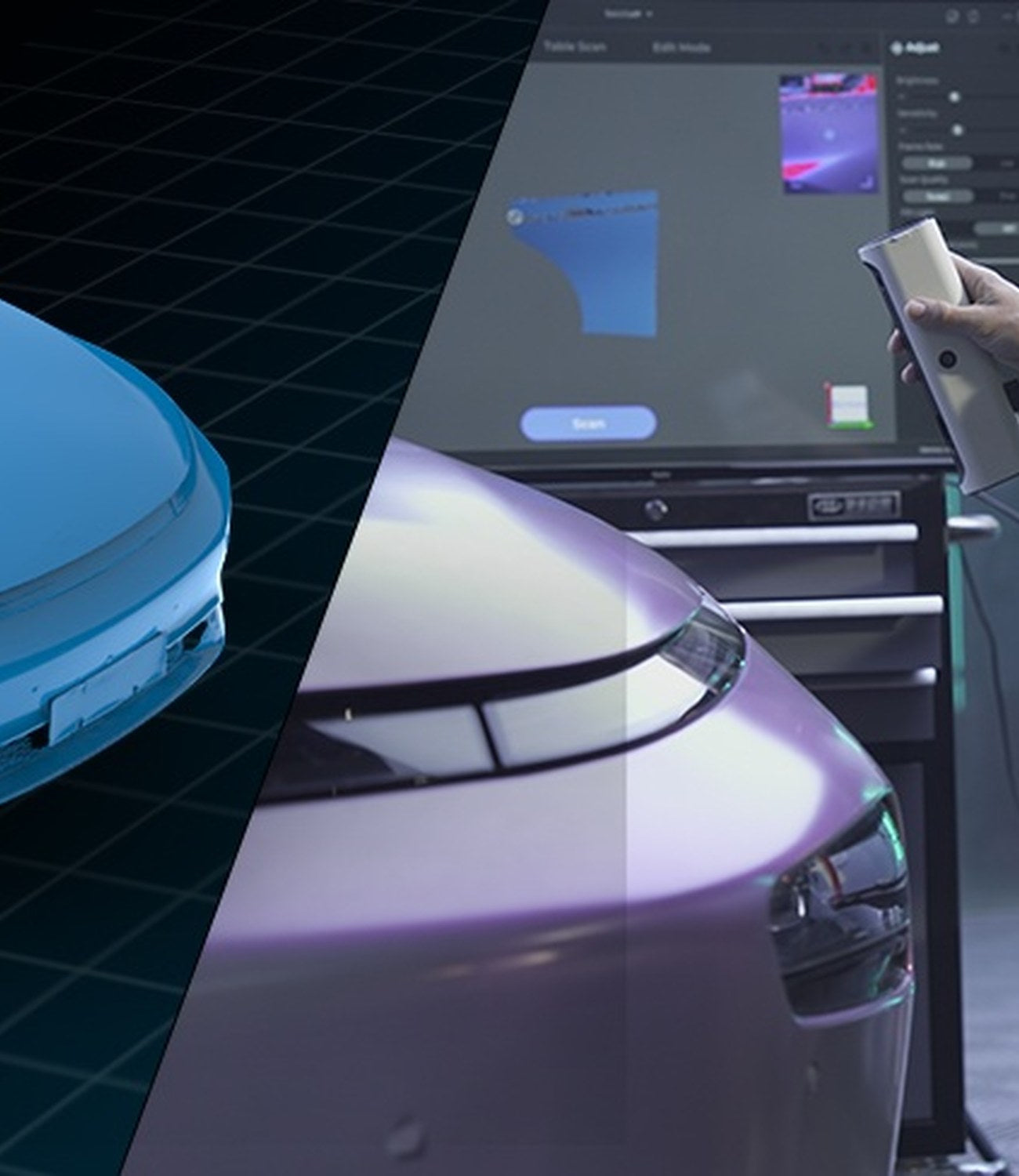

Design esterno

La tecnologia di scansione 3D ha rivoluzionato il settore automobilistico, in particolare nella fase di progettazione dei veicoli. I tecnici possono utilizzare gli scanner per creare modelli virtuali, che possono essere importati in software di progettazione per modifiche e perfezionamenti, consentendo la creazione di concept di veicoli unici e innovativi. Questo processo è conveniente e semplifica la trasformazione delle idee creative in realtà. Una volta finalizzato, il progetto può essere stampato e prodotto, semplificando il percorso dall'ideazione alla produzione. LynxL'intervallo di cattura singola è 250×400 mm, che è il 200% più grande rispetto agli scanner tradizionali di medio formato.

Intestazione

Restauro di parti

Nell'ambito della riparazione e della manutenzione, la scansione 3D offre una soluzione pratica per identificare e risolvere i problemi nei componenti dei veicoli. Scansionando le parti danneggiate, i tecnici possono acquisire misure e dettagli precisi, migliorando l'accuratezza della diagnosi dei problemi. Questa funzionalità è particolarmente utile per i veicoli più vecchi o rari, per i quali i ricambi originali potrebbero non essere più disponibili. Una volta scansionati, questi componenti possono essere replicati con precisione, consentendo la produzione di componenti personalizzati in modo rapido ed efficiente. Questo processo riduce al minimo i tempi di fermo e garantisce il ripristino dei veicoli in condizioni ottimali. Inoltre, Geomagic Wrap per 3DMakerpro software aiuta a realizzare un'efficace reverse engineering.

Intestazione

Misurazione 3D

Il controllo qualità è un'area cruciale in cui la scansione 3D gioca un ruolo fondamentale. Nel processo di produzione, misurazioni precise sono essenziali per garantire che tutti i componenti si incastrino correttamente e soddisfino i rigorosi standard di settore. La scansione 3D consente ai produttori di condurre ispezioni approfondite dei componenti, confrontandoli con modelli CAD per identificare eventuali discrepanze. Questo livello di precisione non solo migliora la qualità del prodotto, ma riduce anche gli sprechi e i costi associati alle rilavorazioni, creando un processo di produzione più efficiente. Inoltre, Geomagic Wrap per 3DMakerpro Il software facilita l'esecuzione di misurazioni 3D efficaci, garantendo la precisione del lavoro.

Intestazione

Parametri

Usa questo testo per condividere informazioni sul tuo marchio con i tuoi clienti. Descrivi un prodotto, condividi annunci o accogli i clienti nel tuo negozio.

0,10 mm

Precisione

5000x5000x5000mm

Area di scansione più ampia

250×400mm

Intervallo di acquisizione singolo

0,30 millimetri

Risoluzione

2.000.000 di punti

Catturato al secondo

100%

Mostra un vantaggio del tuo prodotto

Storie di successo 1

Provando il nuovo Lynx Scanner 3D e creazione di nuove parti: panoramica completa e prime impressioni

Intestazione

Storie di successo 2

Padroneggiare l'arte di realizzare luci posteriori con Lynx Scanner 3D

Intestazione

Storie di successo 3

Scanner 3D di grande formato a meno di $ 400 - Scanner 3D 3D MAKER PRO LYNX

Intestazione

Storie di successo 4

Scansioni 3D di grande formato per tutti!

Intestazione

Prodotti consigliati

Usa questo testo per condividere informazioni sul tuo marchio con i tuoi clienti. Descrivi un prodotto, condividi annunci o accogli i clienti nel tuo negozio.