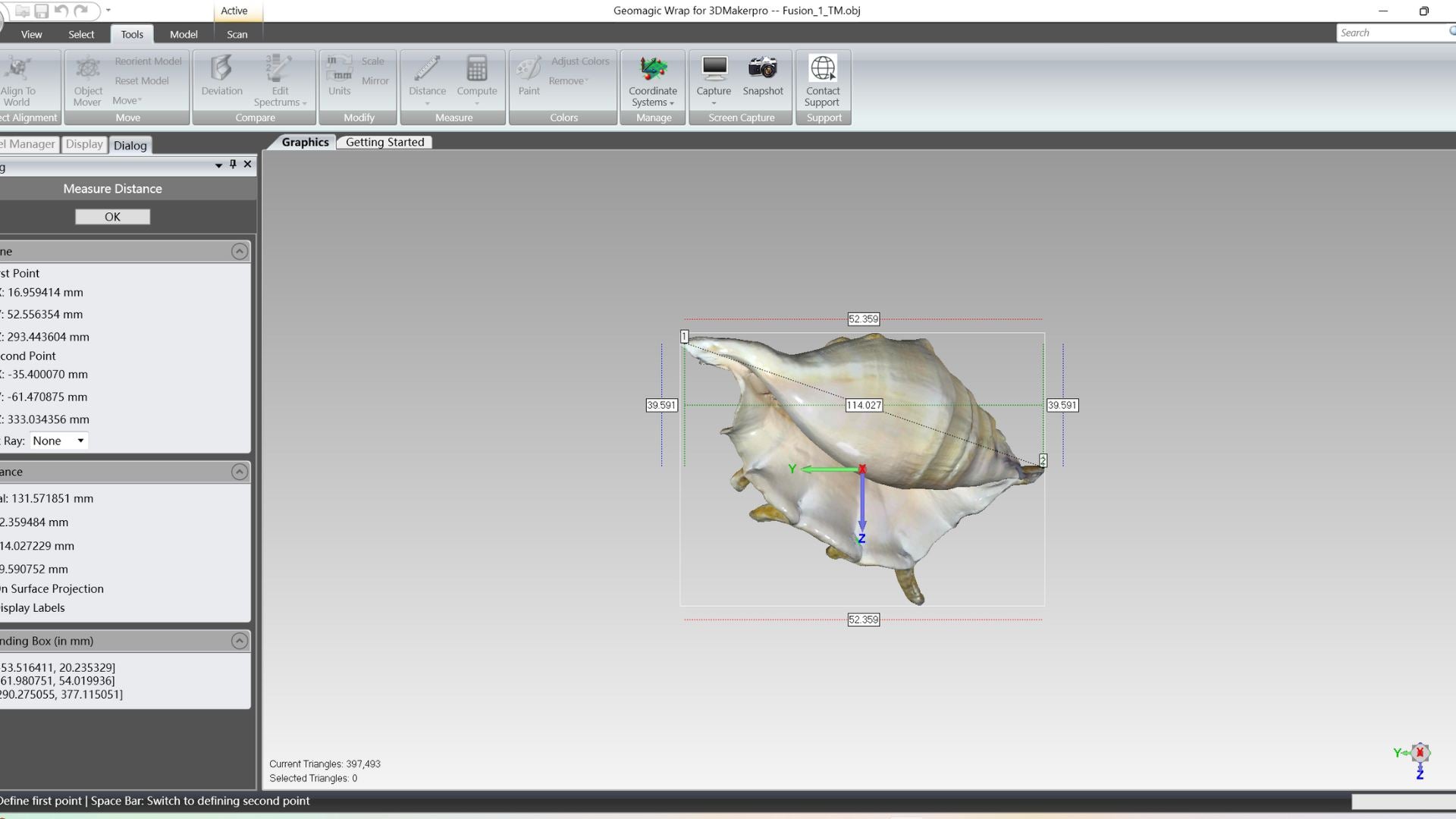

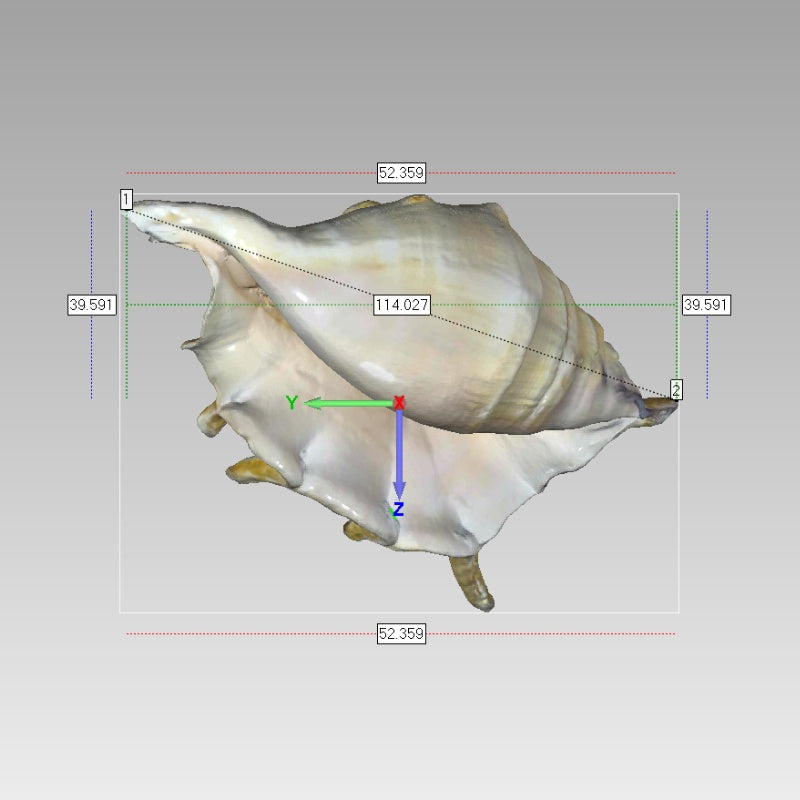

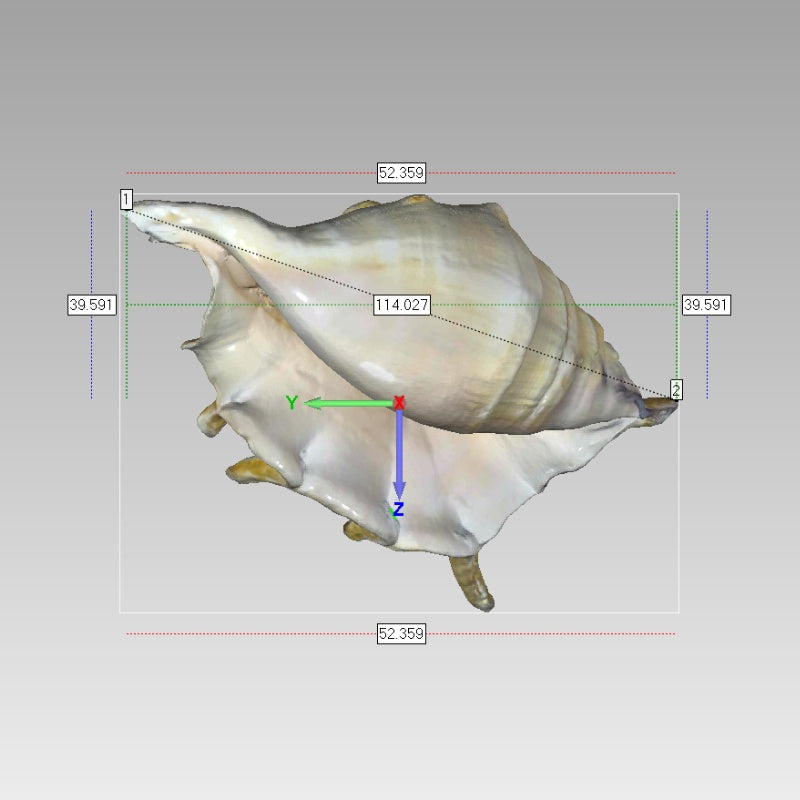

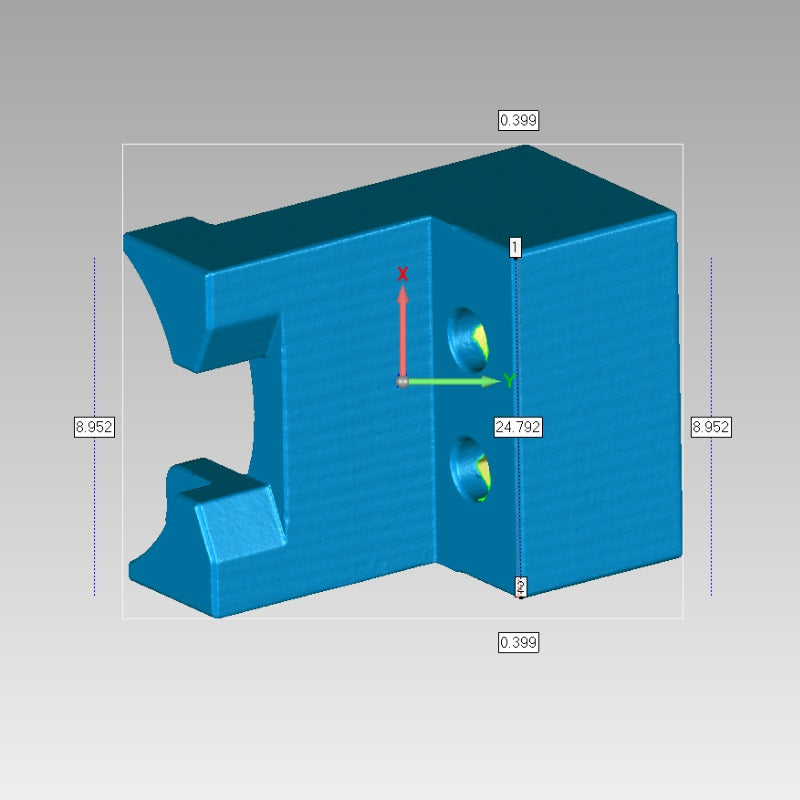

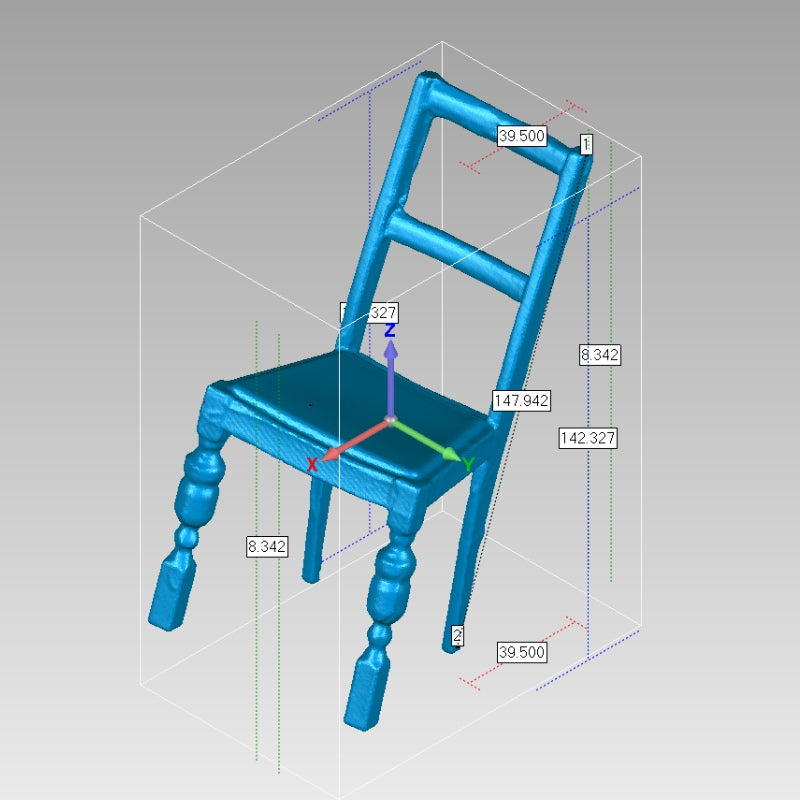

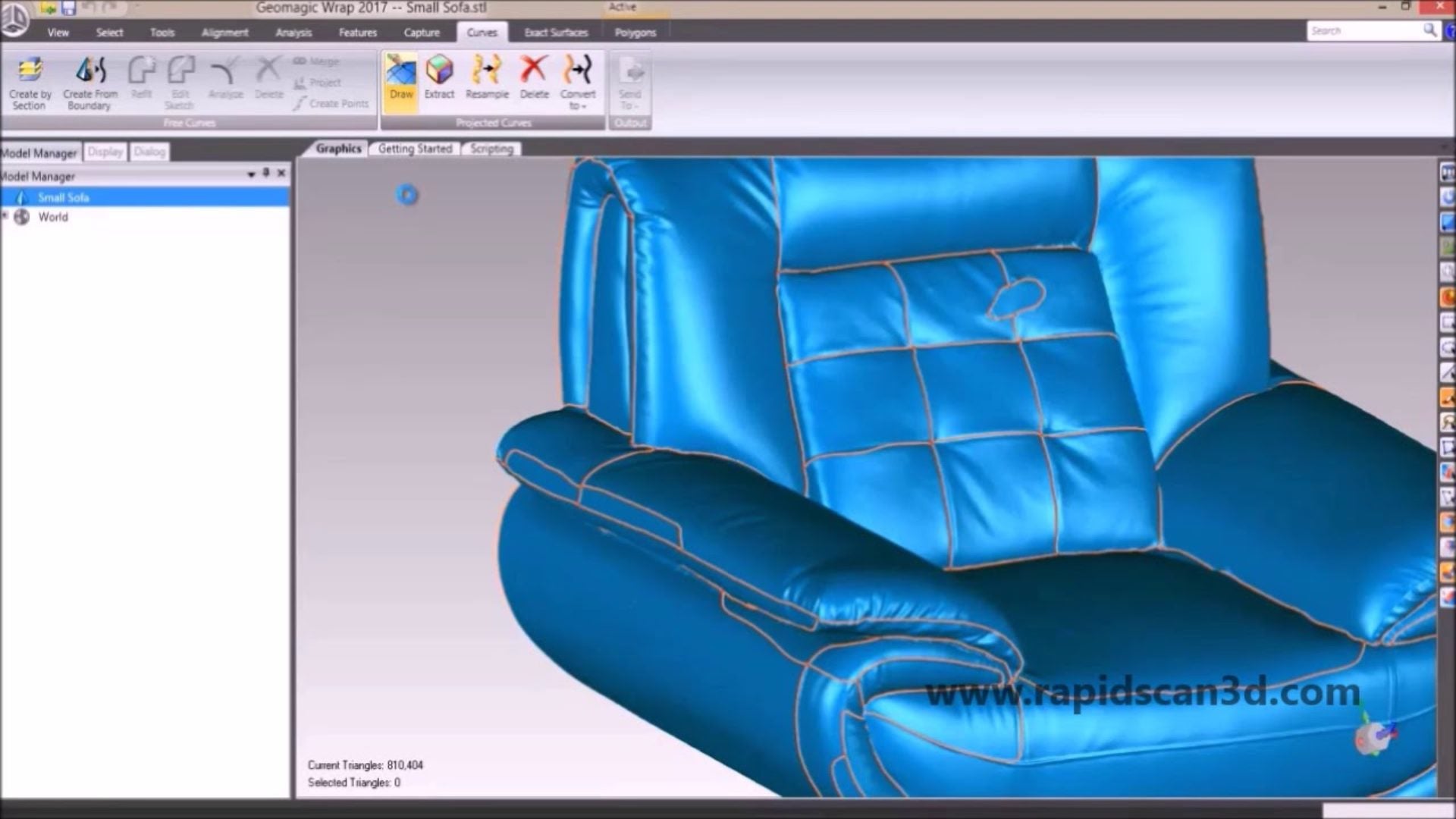

IL scanner 3D di 3DMakerpro Utilizza la tecnologia laser per catturare in modo accurato ed efficiente la forma e le dimensioni tridimensionali di un oggetto, ottenendo un modello digitale altamente dettagliato. Il software di scansione 3D in dotazione Geomagic Wrap per 3DMakerpro Offre funzionalità essenziali come la misurazione 3D, il disegno e la modifica di curve 3D e la conversione CAD automatica di alta qualità. Insieme, questi strumenti offrono una soluzione completa con un'ampia gamma di applicazioni, dal controllo qualità nella produzione alla conservazione del patrimonio culturale, fino al settore sanitario per protesi su misura.

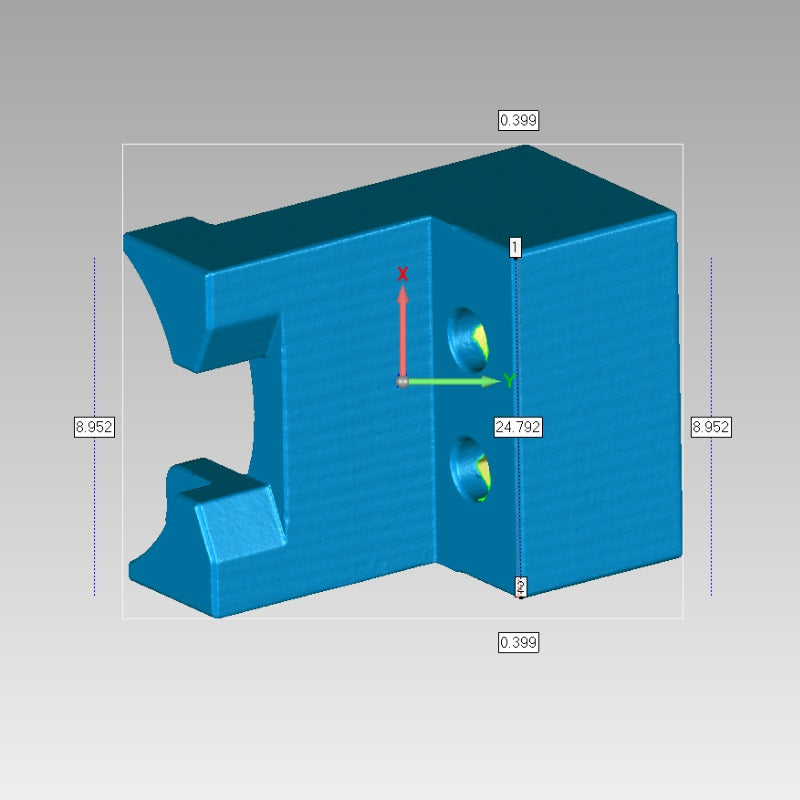

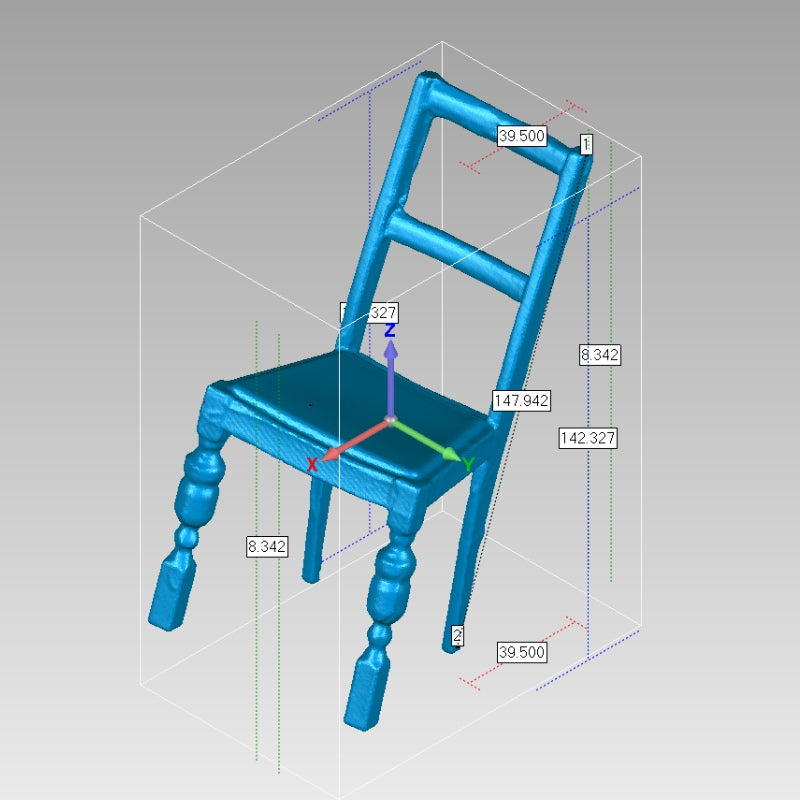

Uno dei principali vantaggi della scansione 3D in misurazione applicazioni è la sua capacità di raggiungere elevati livelli di precisione e accuratezza. I metodi di misurazione tradizionali possono richiedere molto tempo e possono portare a errori umani, mentre gli scanner 3D forniscono rappresentazioni digitali precise degli oggetti, spesso entro precisione micrometricaCiò è particolarmente cruciale in settori come quello manifatturiero e automobilistico, dove anche piccole discrepanze possono causare significativi problemi di prestazioni o rischi per la sicurezza. Utilizzando la scansione 3D, gli ingegneri possono garantire che i componenti si incastrino perfettamente, riducendo al minimo le rilavorazioni e migliorando la qualità complessiva del prodotto.

Oltre alla precisione, la scansione 3D migliora notevolmente l'efficienza dei processi di misurazione. Gli scanner possono catturare geometrie complesse in questione di minuti, riducendo significativamente il tempo necessario per la raccolta dei dati. Questa rapida acquisizione dei dati è particolarmente vantaggiosa nei settori che richiedono tempi di risposta rapidi, come sviluppo e prototipazione del prodottoAccelerando il processo di misurazione, le aziende possono accelerare i loro cicli di progettazione, il che consente loro di rispondere più rapidamente alle richieste del mercato e di mantenere un vantaggio competitivo.

La versatilità della tecnologia di scansione 3D si estende a una vasta gamma di settori. In costruzione e architettura, ad esempio, gli scanner 3D possono creare modelli as-built accurati, aiutando nei progetti di ristrutturazione o nelle nuove costruzioni. In assistenza sanitaria, vengono utilizzati per produrre dispositivi medici su misura, come impianti dentali e supporti ortopedici. Inoltre, in patrimonio culturaleLa scansione 3D consente la documentazione e la conservazione di manufatti e monumenti, garantendone la longevità per le generazioni future. Questa adattabilità rende la scansione 3D uno strumento prezioso per diverse esigenze di misurazione.

Uno dei principali vantaggi della scansione 3D in misurazione applicazioni è la sua capacità di raggiungere elevati livelli di precisione e accuratezza. I metodi di misurazione tradizionali possono richiedere molto tempo e possono portare a errori umani, mentre gli scanner 3D forniscono rappresentazioni digitali precise degli oggetti, spesso entro precisione micrometricaCiò è particolarmente cruciale in settori come quello manifatturiero e automobilistico, dove anche piccole discrepanze possono causare significativi problemi di prestazioni o rischi per la sicurezza. Utilizzando la scansione 3D, gli ingegneri possono garantire che i componenti si incastrino perfettamente, riducendo al minimo le rilavorazioni e migliorando la qualità complessiva del prodotto.

Oltre alla precisione, la scansione 3D migliora notevolmente l'efficienza dei processi di misurazione. Gli scanner possono catturare geometrie complesse in questione di minuti, riducendo significativamente il tempo necessario per la raccolta dei dati. Questa rapida acquisizione dei dati è particolarmente vantaggiosa nei settori che richiedono tempi di risposta rapidi, come sviluppo e prototipazione del prodottoAccelerando il processo di misurazione, le aziende possono accelerare i loro cicli di progettazione, il che consente loro di rispondere più rapidamente alle richieste del mercato e di mantenere un vantaggio competitivo.

La versatilità della tecnologia di scansione 3D si estende a una vasta gamma di settori. In costruzione e architettura, ad esempio, gli scanner 3D possono creare modelli as-built accurati, aiutando nei progetti di ristrutturazione o nelle nuove costruzioni. In assistenza sanitaria, vengono utilizzati per produrre dispositivi medici su misura, come impianti dentali e supporti ortopedici. Inoltre, in patrimonio culturaleLa scansione 3D consente la documentazione e la conservazione di manufatti e monumenti, garantendone la longevità per le generazioni future. Questa adattabilità rende la scansione 3D uno strumento prezioso per diverse esigenze di misurazione.

Storia di successo 1

Cosa PUÒ scansionare?! 3DMakerPro Seal Scanner 3D

Intestazione

Storia di successo 2

Provate in prima persona la sua straordinaria precisione di 0,03 mm | Moose Serie 3D Scanner #3dmakerpro

Intestazione

Storia di successo 3

Qualità di scansione 3D superiore con una curva di apprendimento ripida | 3DMakerpro Moose Recensione dello scanner 3D

Intestazione

Storia di successo 4

Utilizzo di Geomagic Wrap su dati di scansione 3D

Intestazione

Edizioni a confronto

Usa questo testo per condividere informazioni sul tuo marchio con i tuoi clienti. Descrivi un prodotto, condividi annunci o accogli i clienti nel tuo negozio.

Di

Contenuti in primo piano

Organizza i contenuti in più colonne per condividere informazioni utili ai tuoi clienti sui tuoi prodotti, valori...

Essenziale

- Licenza di vita e aggiornamenti gratuiti

- Importa formati di scansione 3D neutri (STL, OBJ, PLY, XYZ, PTS)

- Allineamento e perfezionamento di base da scansione a scansione

- Scansione all'allineamento del sistema di coordinate mondiali

- Modifica punta cloud avanzata

- Guarigione e perfezionamento del poligono avanzato

- Strumenti di misurazione 3D

- Sezione trasversale attraverso i modelli

- Analisi di precisione per solidi 3D

- Esportazione di formati CAD neutri (STEP, IGES)

- Rilevamento ed estrazione automatici delle caratteristiche prismatiche

- Adattamento di funzionalità prismatiche vincolate alle scansioni: punto, linea, piano, sfera, cono, toro, ecc.

- Esportazione delle caratteristiche di adattamento in formati CAD neutri

- Disegno e modifica di curve 3D

- Automatic Surfacing - Conversione rapida da poligoni a CAD

Un po

Abbina il testo a un'immagine per concentrarti sul prodotto, la collezione o il post del blog che hai scelto. Aggiungi dettagli su disponibilità, stile o fornisci anche una recensione.

Prodotti consigliati

Usa questo testo per condividere informazioni sul tuo marchio con i tuoi clienti. Descrivi un prodotto, condividi annunci o accogli i clienti nel tuo negozio.