Lors d'une numérisation 3D, il est courant de rencontrer divers défis. Aujourd'hui, nous allons décrire dix erreurs courantes et vous donner des conseils pour vous aider à les surmonter efficacement.

1. Choisissez des objets complexes

Les scanners excellent dans la reproduction d'images, mais certains matériaux peuvent poser problème. Les couleurs sombres (comme le noir ou le rouge) , les surfaces brillantes et transparentes, ainsi que les surfaces métalliques, réfléchissent souvent mal la lumière, ce qui rend difficile la capture des détails par les scanners. Pour améliorer les résultats, utilisez Spray de numérisation bleu AESUB, qui améliore la visibilité sans éblouissement. Ce spray est incolore et se dissipe avec le temps, éliminant ainsi le besoin de nettoyage. Cependant, évitez tout contact avec les enfants et les animaux domestiques, et ne vaporisez pas près du visage. Visez 15 à 20 cm au-dessus de la surface de l'objet et vaporisez en diagonale. Vous pouvez également utiliser notre Taupe ou Baleine scanners, qui fonctionnent bien avec des objets sombres et dans des conditions de faible luminosité.

Le deuxième cas se présente lorsque l'objet présente des parties creuses ou est relativement fin, ce qui peut facilement entraîner un échec de numérisation. Il est donc recommandé de choisir un scanner offrant une zone de numérisation plus large ou une précision de numérisation supérieure. Vous pouvez également essayer le spray mentionné précédemment.

2. Négliger la préparation de la surface

Un modèle propre est essentiel à la réussite d'une numérisation. Un objet sale ou poussiéreux complique les étapes de numérisation et de traitement, ce qui altère votre modèle numérique. Avant de numériser, essuyez délicatement les objets avec un essuie-tout humide ou utilisez un modèle impeccable.

3. Non Ajuster l'exposition

Ajuster l'exposition avant la numérisation est essentiel pour une clarté optimale. Faites simplement glisser la barre de progression des paramètres d'exposition pour améliorer la visibilité. Vous pouvez également effectuer des ajustements pendant la numérisation pour mieux répondre à vos besoins.

4. Sélection du scanner inadapté

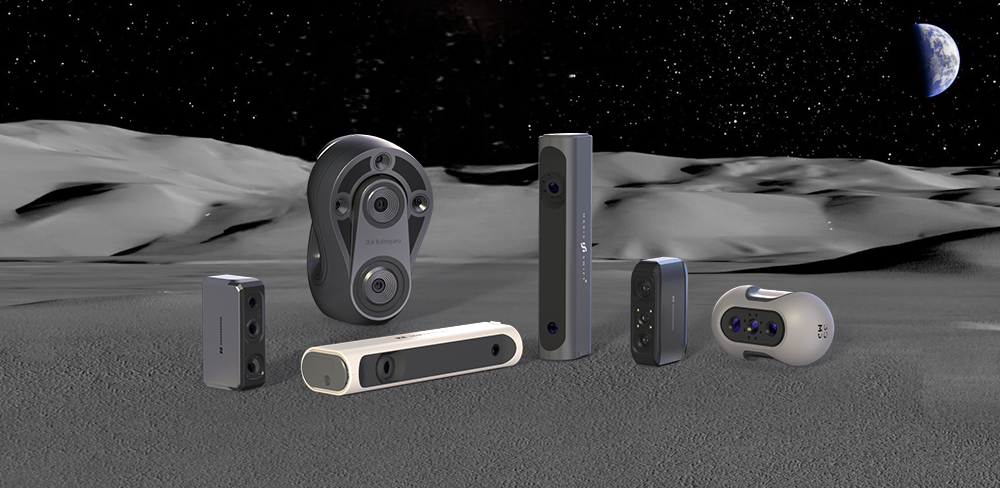

Chaque scanner possède ses propres caractéristiques ; il est donc important de choisir le bon pour gagner du temps et optimiser vos résultats. Par exemple, Scanner de sceaux est mieux adapté aux pièces de monnaie que le Scanner LynxSi vous choisissez le scanner Lynx, vous obtiendrez peut-être un objet rond sans motif. En revanche, le scanner Seal pourra restituer magnifiquement ses détails de texture et ses couleurs. De plus, Scanner d'élan dispose de textures couleur 24 bits, qui affichent facilement la couleur d'origine de l'objet et sont faciles à aligner pour plusieurs données de numérisation. Taupe Seul un kit de coloration supplémentaire permet d'obtenir des résultats similaires. Le choix d'un outil adapté est donc crucial.

5. Aller trop vite

La vitesse de déplacement est essentielle à la réussite d'une numérisation. Si vous vous déplacez trop vite, surtout avec des objets volumineux, vous risquez de perdre le suivi. Dans ce cas, revenez lentement au dernier point de suivi connu. Certains scanners ont une portée de capture limitée ; des mouvements plus lents sont donc souvent nécessaires. De plus, soyez prudent lorsque vous utilisez une table tournante, car un déplacement trop rapide peut parfois compliquer le retour à la position initiale.

6. Perte de suivi

La perte de suivi peut être due à divers facteurs, notamment la couleur, le matériau, la structure et la vitesse de déplacement de l'objet. Si vous rencontrez des problèmes de suivi, pas de panique ; ajustez simplement l'angle de balayage et la distance par rapport à l'objet. Soyez attentif à votre distance par rapport à l'objet, car trop près ou trop loin peut perturber le suivi. Surveillez l'indicateur de distance du côté gauche du scanner : le bleu indique une distance idéale, tandis que le rouge suggère que vous êtes trop près ou trop loin. Logiciel JM Studio fournit des rappels en temps réel pour vous aider.

7. Misalignment

Un mauvais alignement se produit souvent lors d'une numérisation à grande vitesse ou si votre main est inclinée. La seule solution est de numériser à nouveau, car un mauvais alignement peut entraîner des ombres doubles ou plusieurs images incorrectes. Imaginez une petite pourriture sur une pomme : l'ignorer pourrait entraîner des problèmes plus graves. Un redémarrage rapide garantira un flux de travail plus efficace. De plus, certains scanners sont plus sujets aux mauvais alignements avec des objets spécifiques ; il est donc conseillé de faire des tests.

8. Alignement manuel incorrect

Une fois vos numérisations terminées, vous devrez peut-être procéder à l'alignement, un processus fastidieux. Bien que l'alignement automatique soit efficace, il peut s'avérer insuffisant pour les éléments complexes. L'alignement manuel est nécessaire pour combiner des données sous plusieurs angles, notamment le recto, le côté gauche, le verso, le haut ou le bas. Lorsque vous numérisez sous différents angles, assurez-vous de répéter certaines positions afin de créer des points de jonction pour l'alignement. Autre astuce : lorsque vous cliquez sur le bouton « Confirmer » une fois l'alignement terminé, les différents objets numérisés seront fusionnés en un seul, irréversible et non modifiable. En cas de doute et de besoin de réalignement, choisissez directement la procédure suivante : Traiter. Répétez cette opération plusieurs fois pour simplifier l'opération !

9. Utiliser les mauvais espaces de réparation

L'option « Réparer les espaces vides » peut être utile, mais elle ne convient qu'aux objets sans creux ni trous. Si vous numérisez un cerf ou un chevreuil, choisissez « Réparer les espaces vides » , ce sera un désastre. Le matériau de remplissage infusera dans tout le vase, empêchant ainsi votre impression de contenir les fleurs. Votre cerf deviendra étrange et aura plus de quatre pattes. Il est donc conseillé de bien réfléchir avant de choisir cette option. En règle générale, supprimez le bruit et les parties flottantes ; ces deux fonctions répondent parfaitement à vos besoins. Pour combler des espaces vides, nous vous recommandons d'utiliser Geomagic Wrap pour le logiciel 3DMakerpro pour découvrir les fonctions de maillage médical et de remplissage de trous.

10. Mauvaise suppression du bruit

Il s'agit d'une fonction simple mais puissante. Comme mentionné précédemment, sélectionnez les fonctions de suppression automatique du bruit et des parties flottantes. Pour une suppression manuelle, utilisez les outils de lasso (rectangle, polyligne, cercle, point) pour sélectionner et appuyez sur la touche « Suppr » pour supprimer les zones indésirables. Vous pouvez également maintenir la touche « Ctrl » enfoncée tout en faisant glisser la souris pour sélectionner les parties inutiles, puis les supprimer. Vérifiez toujours vos sélections afin d'éviter de supprimer involontairement des détails essentiels au modèle numérique en 3D. Vous pourriez sélectionner par inadvertance l'avant et l'arrière en même temps et les supprimer par erreur.

Enfin, n'oubliez pas qu'une pratique assidue est essentielle. Bien que ces précautions puissent paraître complexes, une pratique régulière vous aidera à éviter les erreurs et à améliorer vos compétences en numérisation 3D. Bonne chance pour votre expérience de numérisation !