Les scanners 3D rencontrent souvent des difficultés importantes lors de la numérisation d'objets transparents, principalement parce que la lumière traverse directement ces matériaux au lieu de se refléter sur leur surface. Cette propriété intrinsèque empêche le détecteur du scanner de capturer les données 3D nécessaires, ce qui entraîne des numérisations incomplètes ou déformées. Par conséquent, obtenir une représentation précise d'objets transparents peut s'avérer particulièrement difficile dans diverses applications, allant de l'art et du design à l'ingénierie et à la fabrication.

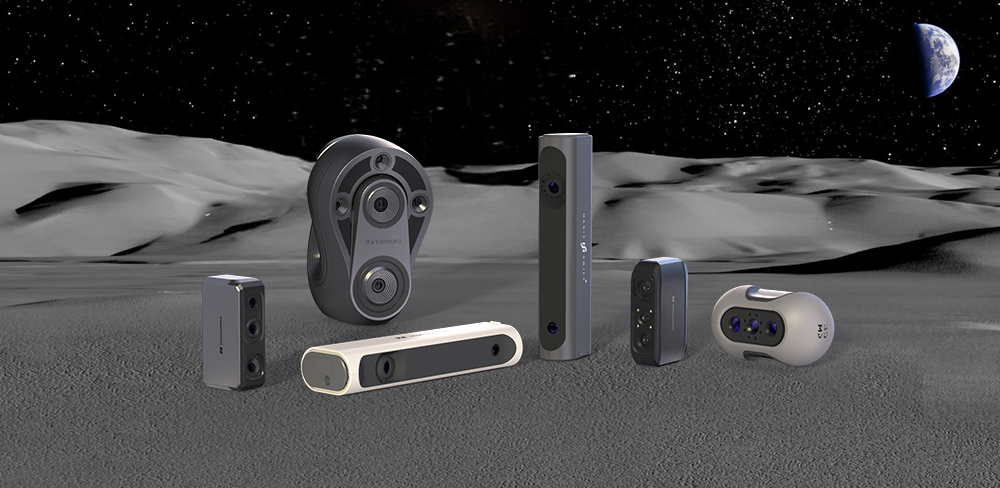

Heureusement, 3DMakerpro propose des services professionnels scanners 3D, tels que les scanners Moose et Seal, spécialement conçus pour relever efficacement ces défis et fournir des résultats de haute qualité.

Scanner 3D d'orignal

Le Scanner d'élan se distingue par ses spécifications impressionnantes, notamment exceptionnelles 0, 03 mm précision et 0, 07 mm résolution. Il intègre un mode de suivi visuel par IA qui améliore sa capacité à traiter les formes complexes et les détails les plus précis. Associé à une lumière LED bleue intelligente, le scanner Moose peut capturer une large gamme de tailles d'objets, de 15 mm à 1500 mmCette polyvalence en fait un choix idéal pour diverses applications, que vous capturiez des motifs délicats ou des composants transparents plus grands.

Scellez le scanner 3D

Le Scanner de sceaux est réputé pour sa précision remarquable, avec une précision de 0, 01 mm et une résolution de 0, 05 mmCes caractéristiques le rendent particulièrement efficace pour capturer les détails les plus fins d'objets plus petits, tels que la verrerie délicate ou les prototypes complexes. Doté d'un mode de suivi visuel, le scanner Seal peut scanner efficacement des objets dans un rayon de 10 mm à 300 mmIl prend également en charge plusieurs formats de sortie, notamment OBJ, STL, PLY et ASC, offrant une flexibilité pour différents flux de travail et applications logicielles.

Pour des résultats optimaux, il est conseillé d'utiliser les deux scanners en conjonction avec Spray de balayage bleu AESUBCe spray spécialisé optimise le processus de numérisation en offrant une finition mate qui améliore l'absorption de la lumière, garantissant ainsi une capture plus précise des données pour les éléments transparents. En combinant ces technologies de numérisation avancées avec une préparation adéquate, vous pouvez obtenir des modèles 3D haute fidélité répondant aux exigences de vos projets.

Exemples de numérisation

Le scanner Moose scanne le verre transparent

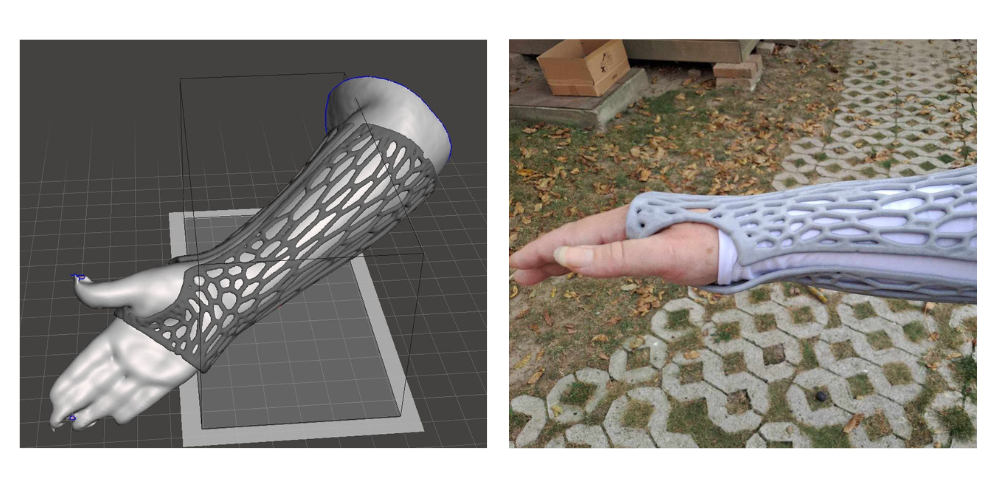

Lors de la numérisation de verre transparent, il peut être difficile d'identifier directement l'objet, même en ajustant la luminosité. Pour améliorer la visibilité, il est essentiel d'appliquer le spray de numérisation bleu AESUB. Une fois le verre traité, Scanner d'élan le capture dans une couleur blanche.

Pour restaurer pleinement l'aspect d'origine de l'objet, il est nécessaire de le numériser sous plusieurs angles. Commencez par numériser de face, en effectuant une rotation complète pour couvrir tous les détails. Ensuite, positionnez l'objet sur le côté et numérisez le côté gauche pour capturer précisément la profondeur et le fond de la bouteille en verre. Sinon, l'image risque de manquer des parties et des creux, ce qui entraînera un remplissage incorrect par le logiciel. Numérisez ensuite un autre côté de la même manière.

Après la numérisation, supprimez tout bruit superflu et activez la fonction d'alignement automatique. Si les données de numérisation sont correctes, l'alignement automatique sera excellent. En revanche, si des données sont manquantes, l'alignement automatique et l'alignement manuel risquent de ne pas être parfaits. Soyez patient et assurez-vous que l'objet est entièrement recouvert. Si l'effet du spray disparaît, réappliquez. Spray de balayage bleu AESUB pour des résultats optimaux.

Enfin, traitez vos données numérisées en sélectionnant « Suppression statistique du bruit » , « Fusion » , « Supprimer les parties flottantes » et « Mappage de texture » . Le modèle numérique obtenu sera de haute qualité et vous pourrez modifier tous les détails supplémentaires à l'aide de Geomagic Wrap pour 3DMakerpro.

Le scanner de sceaux scanne le verre transparent

Le processus de numérisation du scanner Seal est similaire à celui du scanner Moose. Cependant, veuillez garder à l'esprit les conseils suivants :

a) Distance de balayage

Assurez-vous que la distance de lecture n'est ni trop proche ni trop éloignée. La distance de travail optimale pour le scanner de sceaux se situe entre 180 mm et 280 mmVous pouvez surveiller l'échelle de distance sur le côté gauche de l'interface du logiciel.

b) Angle de balayage

Veuillez prêter attention à l'angle de numérisation afin d'éviter les erreurs d'alignement dues à des écarts importants dans la façon dont vous tenez le scanner. Heureusement, Scanner de sceaux Il dispose d'une fonction d'auto-étalonnage intelligente. Si vous constatez un défaut d'alignement important sur l'écran, attendez la fin de la numérisation avant de supprimer les données. Le résultat final pourrait être précis.

c) Configuration informatique requise

Plusieurs analyses peuvent ralentir votre ordinateur. Pour des performances optimales avec le scanner Seal, la configuration recommandée est un processeur Intel Core i7 (8e génération) , 16 Go de RAM et un GPU NVIDIA 3060 avec 4 Go de VRAM. La configuration minimale requise est un processeur Intel Core i5 (8e génération) , 16 Go de RAM et un GPU MX250 avec 2 Go de VRAM. Pour un traitement efficace, nous recommandons un ordinateur haut de gamme.

d) Fonction Annuler

Si vous supprimez accidentellement une partie du modèle virtuel, vous pouvez cliquer sur le bouton Annuler situé à l'extrême droite de la barre de fenêtre en haut pour revenir à l'étape précédente.

e) Cartographie des textures

Si vous n'avez pas besoin d'afficher le modèle numérique, vous pouvez ignorer la fonction de mappage de texture pour gagner du temps. Puisque nous utilisons Spray de balayage bleu AESUBLe modèle numérique final apparaîtra blanc plutôt que transparent. Si vous prévoyez d'imprimer le modèle, vous pouvez choisir la couleur de filament de votre choix.

f) Qualité de l'image

Le scanner Seal offre une imagerie plus précise que le scanner Moose, avec une précision de 0, 01 mm et une résolution de 0, 05 mm, contre 0, 03 mm et 0, 07 mm pour le Moose. Cependant, le traitement avec le scanner Seal peut prendre plus de temps, environ 20 minutes, par rapport au Moose, qui prend environ 10 minutes.

À partir de cette vidéo et du texte précédent, nous espérons que vous avez appris à numériser des objets transparents en utilisant à la fois le Scanners d'orignaux et de phoquesLe processus est relativement simple. Si vous rencontrez des difficultés lors de la numérisation, n'hésitez pas à laisser un commentaire afin que nous puissions en discuter et résoudre le problème ensemble. N'oubliez pas : deux têtes valent mieux qu'une.