La integración de escáneres 3D en la impresión 3D ofrece soluciones robustas para duplicar, modificar y reparar Objetos en diversas industrias. Su capacidad para crear representaciones digitales precisas no solo mejora la eficiencia del proceso de diseño, sino que también fomenta la innovación en el desarrollo de productos. A medida que la tecnología avanza, las aplicaciones del escaneo 3D seguirán expandiéndose, impulsando nuevas mejoras en las capacidades y prácticas de impresión 3D.

Modelos 3D

Duplicando

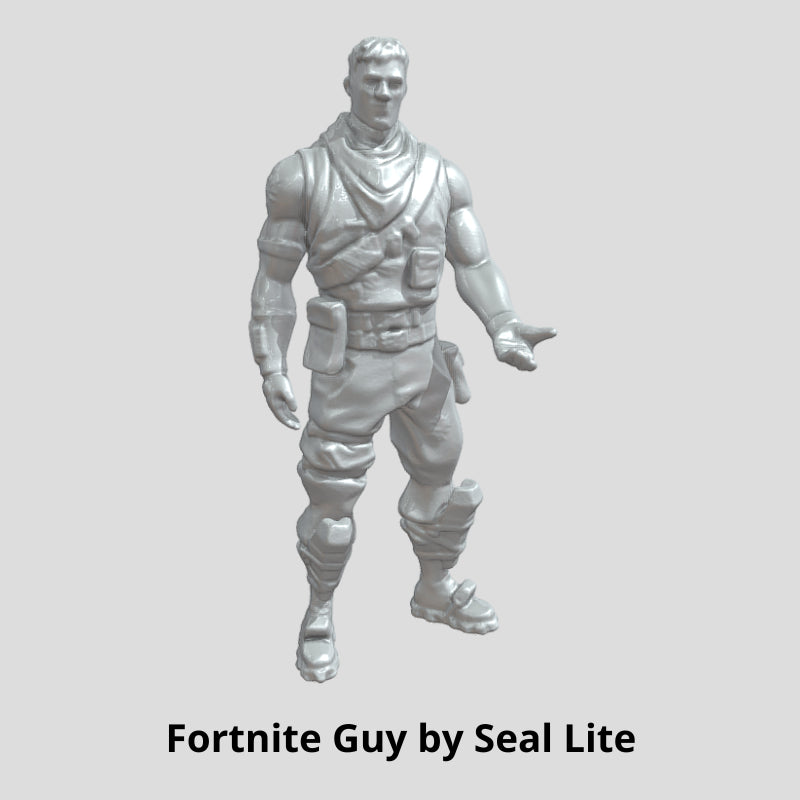

Una de las funciones principales de los escáneres 3D es duplicar objetos existentes. Seal escáner, con su Precisión de 0,01 mm y lentes antivibración, recoge 100.000 puntos por segundoEsto mejora esta capacidad. Permite a los usuarios crear réplicas digitales precisas de objetos físicos, que luego pueden modificarse o imprimirse directamente. En sectores como la restauración de arte, la preservación del patrimonio y la manufactura, la duplicación de objetos garantiza la conservación de los detalles intrincados y la reproducción precisa de los diseños originales.

Seal ¡El escáner 3D escanea la Torre Eiffel de los Juegos Olímpicos de París!

Modificación y reparación

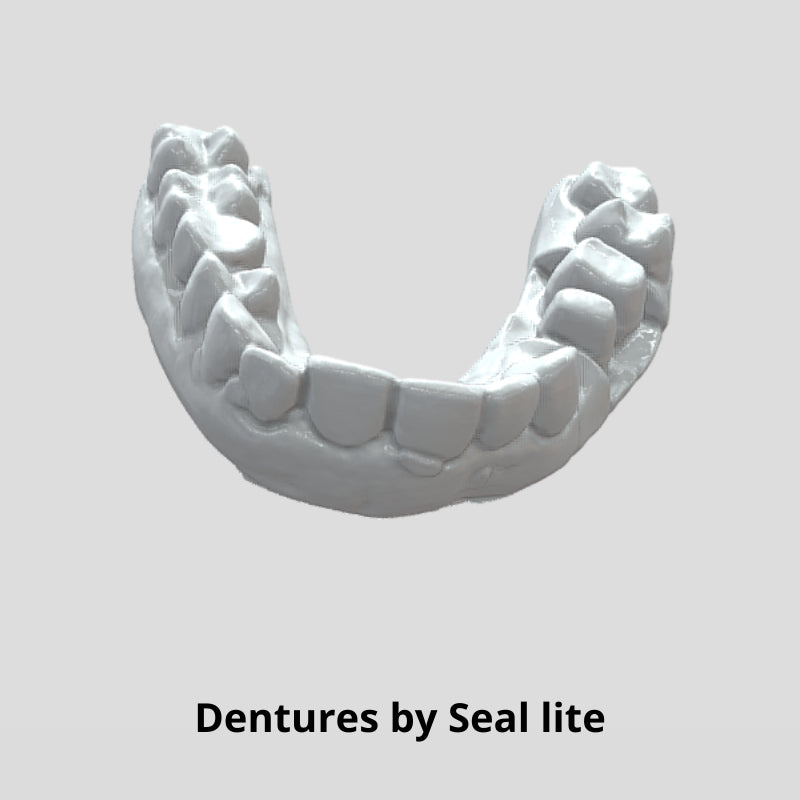

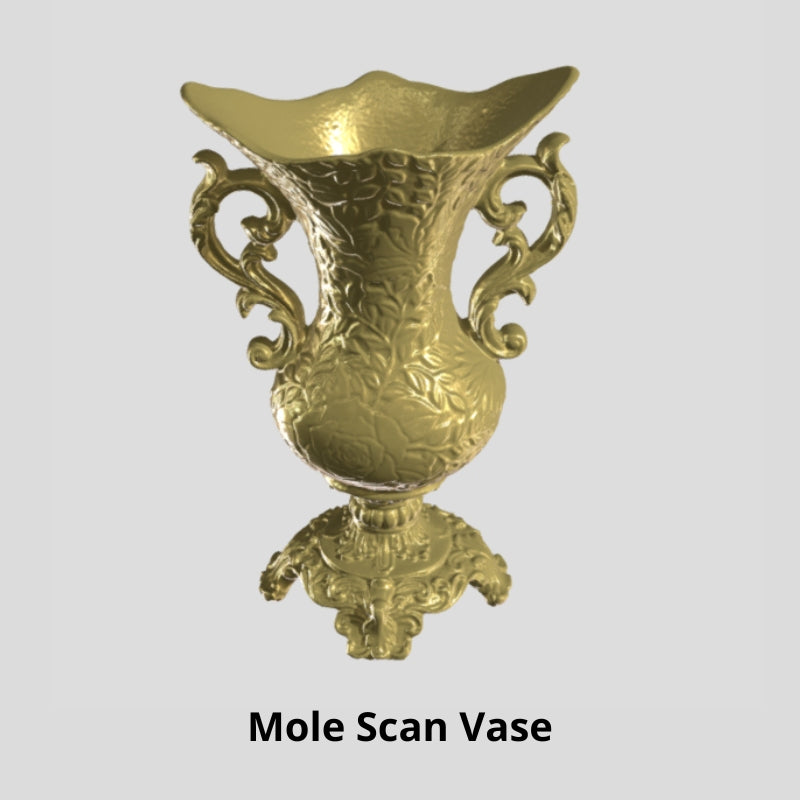

Además de la duplicación, los escáneres 3D se destacan en la modificación y reparación de diseños existentes. Mole escáner poder capturar objetos que van desde en tamaño desde 15 a 1500 milímetros y cuenta con un modo de textura ultra clara, con Precisión de 0,05 mm y Resolución de 0,1 mmAl importar un objeto escaneado a un software de modelado 3D, se puede modificar para cumplir con requisitos específicos. Este proceso es especialmente útil en sectores como la salud, donde se pueden adaptar dispositivos médicos o prótesis a las necesidades individuales. Además, se pueden escanear los artículos dañados, lo que permite diseñar e imprimir reparaciones, prolongando así la vida útil de los productos y reduciendo los residuos. Esta adaptabilidad convierte al escaneo 3D en una potente herramienta para la innovación y la eficiencia.

Crea una cápsula de triple calibre con The Mole Escáner 3D

Aplicación amplia

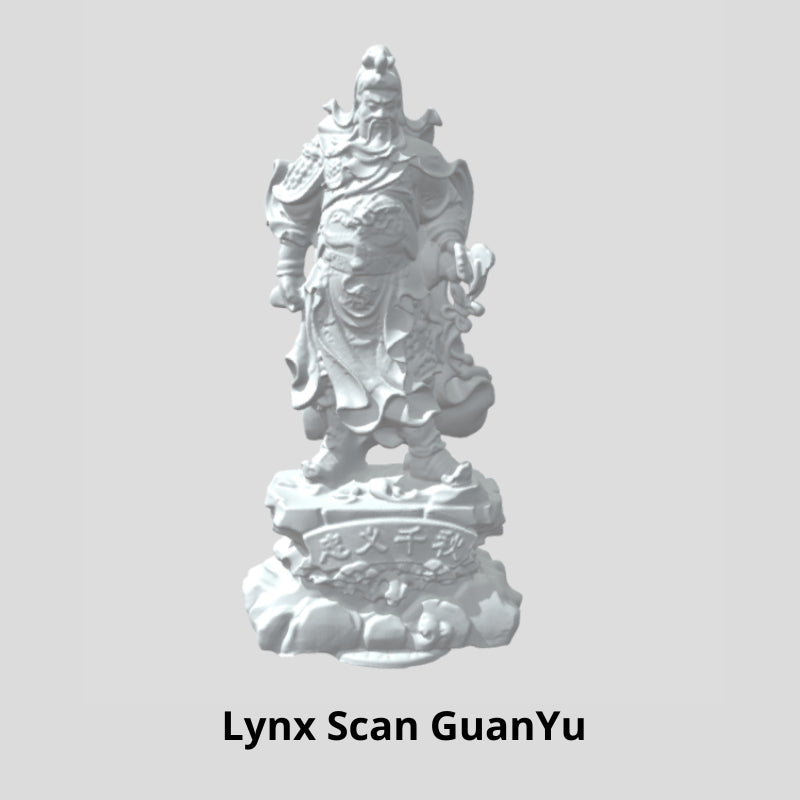

El amplio campo de aplicación del escaneo 3D subraya aún más su importancia en la impresión 3D. Industrias como la automotriz, la moda y la arquitectura utilizan esta tecnología. En el diseño automotriz, por ejemplo, los escáneres 3D pueden capturar los detalles intrincados de las piezas de los automóviles para la creación de prototipos y pruebas. En el ámbito de la moda, los diseñadores pueden crear prendas personalizadas que se adaptan perfectamente a las formas corporales individuales. Además, los estudios de arquitectura utilizan el escaneo 3D para crear modelos precisos de edificios para proyectos de renovación, garantizando que los nuevos diseños se integren a la perfección con las estructuras existentes. LynxEl rango de captura única es de 250 × 400 mm, que es 200% más grande que los escáneres tradicionales de formato medio. Con Lynx, puedes escanear objetos hasta 5000x5000x5000mm, una friolera Mejora del 3700%!

Escáner 3D de gran formato por menos de $400 - Escáner 3D 3D MAKER PRO LYNX

Comparar

Especificaciones del producto

Especificaciones del producto

0,01 mm

0,05 mm

0,10 mm

0,05 mm

0,1 mm

0,30 mm

10 fps

10 fps

10 fps

Seguimiento visual

Seguimiento visual

Seguimiento visual

180-280 mm

150-400 mm

400-900 mm

100x75 mm

200x100 mm

250x400 mm

10-300 mm

15-1500 mm

100-2000 mm

Luz azul

NIR

NIR

Apoyo

Soporte extendido

Soporte extendido

110×60×35 mm

141x80x80m m

244 x 75 x 48 mm

254G

390 gramos

800 gramos

Historia de éxito 1

3DMakerpro Seal Escáner 3D - Desempaquetado

Historia de éxito 2

3DMaker Pro Mole Análisis del escáner 3D: un excelente escáner para objetos de tamaño mediano

Historia de éxito 3

3DMaker Pro Lynx Desempaquetado y primer escaneo

Título

Recomendar Productos

Utilice este texto para compartir información sobre su marca con sus clientes. Describe un producto, comparte anuncios o da la bienvenida a los clientes a tu tienda.

Seal Escáner 3D

Escáner 3D Mole