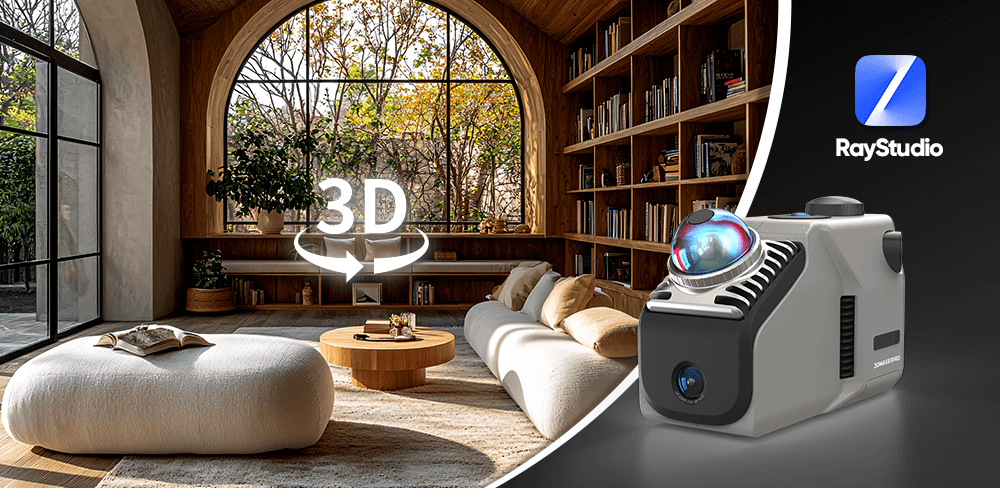

Ces dernières années, la numérisation 3D a connu un essor considérable dans divers secteurs, de l'architecture et de la construction aux jeux vidéo et à la réalité virtuelle. Face à l'évolution constante de la technologie, l'unité de mesure inertielle (IMU) est un composant essentiel qui améliore la précision et l'efficacité des systèmes de numérisation 3D. qu'est-ce qu'une IMU ? Ce blog explorera ce qu'est une IMU, comment elle fonctionne et pourquoi elle est importante dans la numérisation 3D, en particulier dans le contexte de la numérisation avancée Scanner LiDAR Eagle.

Qu'est-ce qu'une IMU ?

Une unité de mesure inertielle (IMU) est un appareil sophistiqué qui mesure la force spécifique d'un objet, sa vitesse angulaire et, dans certains cas, le champ magnétique environnant. Ses principaux composants comprennent un accéléromètre et un gyroscope, certains modèles étant équipés d'un magnétomètre intégré (remarque : 3DMakerproLe scanner Eagle LiDAR n'inclut pas de magnétomètre.

Accéléromètres :

-

Principe : Basé sur la deuxième loi de Newton (F=ma) , ce capteur détecte le mouvement linéaire en mesurant l'accélération dans trois directions orthogonales (X, Y et Z) .

-

Fonction : Fournit des données d'accélération sur trois axes pour détecter les changements de mouvement et de posture.

- Sortir : Données d'accélération sur trois axes (a, a, a) , généralement en m/s² ou g (accélération due à la gravité) .

Gyroscopes :

-

Principe : Utilisant la conservation du moment angulaire, ce capteur détecte le mouvement de rotation en mesurant la vitesse angulaire autour de trois axes (X, Y et Z) .

-

Fonction : Fournit des informations sur la vitesse angulaire à trois axes pour suivre la rotation de l'appareil et les changements d'attitude (tels que le lacet et le tangage) .

- Sortir : Données de vitesse angulaire sur trois axes (c) en rad/s.

Fusion et intégration de données

- À l'estime : Les changements d'angle obtenus en intégrant le gyroscope sont combinés avec la référence de gravité fournie par l'accéléromètre (pour corriger la dérive) pour estimer l'attitude en temps réel de l'appareil (par exemple, les angles d'Euler ou les quaternions) .

- À l'estime : L'estimation de la position peut être calculée par intégration quadratique des données de l'accéléromètre. Cependant, les erreurs s'accumulent au fil du temps et nécessitent une correction à l'aide d'autres capteurs (tels que le GPS et le LiDAR) .

- Algorithmes de filtrage : Le filtrage de Kalman ou le filtrage complémentaire sont couramment utilisés pour fusionner les données de l'accéléromètre et du gyroscope, éliminant ainsi les erreurs accumulées à partir d'un seul capteur et améliorant la stabilité et la précision de l'estimation de l'attitude.

Les fonctions principales d'une IMU

1. Estimation de l'attitude

L'IMU mesure l'accélération et la vitesse angulaire de l'appareil pour en déduire son inclinaison, sa rotation et son orientation (tangage, roulis et lacet, par exemple) . Ces informations d'attitude sont cruciales pour le traitement des données lidar, par exemple :

Correction des écarts d'attitude dans les données de nuage de points pour garantir un alignement précis du nuage de points dans l'espace tridimensionnel.

Lors du balayage lidar, les mouvements de l'appareil (vol d'un drone ou déplacement d'un robot, par exemple) peuvent entraîner une distorsion du nuage de points. Les informations d'attitude fournies par l'IMU peuvent être utilisées pour une correction en temps réel, améliorant ainsi la qualité du nuage de points.

2. Compensation de mouvement

Le LiDAR mesure les distances environnementales en émettant des faisceaux laser, mais les mouvements de l'appareil (tels que les vibrations et l'accélération) peuvent introduire des erreurs. L'IMU compense le mouvement du lidar en mesurant le mouvement de l'appareil à haute fréquence, réduisant ainsi les erreurs de mesure dans les environnements dynamiques.

Dans des scénarios tels que la conduite autonome et la navigation par drone, la fusion des données IMU et lidar permet une localisation et une cartographie en temps réel de haute précision (SLAM) .

3. Fusion de capteurs assistée

Les IMU sont souvent utilisées en conjonction avec d'autres capteurs (tels que GPS, compteurs de vitesse de roue et caméras) pour améliorer la robustesse du système grâce à la fusion de données multicapteurs. Par exemple :

Lorsque le signal GPS est perdu (par exemple dans les tunnels ou à l'intérieur) , les IMU peuvent fournir une navigation inertielle de haute précision à court terme pour maintenir la continuité du positionnement.

La fusion avec les données du compteur de vitesse de roue peut optimiser davantage l'estimation de la pose et réduire l'erreur cumulative.

Pourquoi une IMU est-elle importante dans la numérisation 3D ?

1. Précision améliorée

L'un des principaux avantages de l'intégration d'une IMU à un système de numérisation 3D, comme le scanner LiDAR Eagle, est l'amélioration significative de la précision. Le scanner Eagle offre des niveaux de précision exceptionnels de 2 cm à 10 m, 3 cm à 20 m et 5 cm à 40 m. Une telle précision est essentielle pour les applications de conception, de topographie et d'ingénierie, où même des écarts mineurs peuvent entraîner des erreurs coûteuses.

2. Suivi de mouvement en temps réel

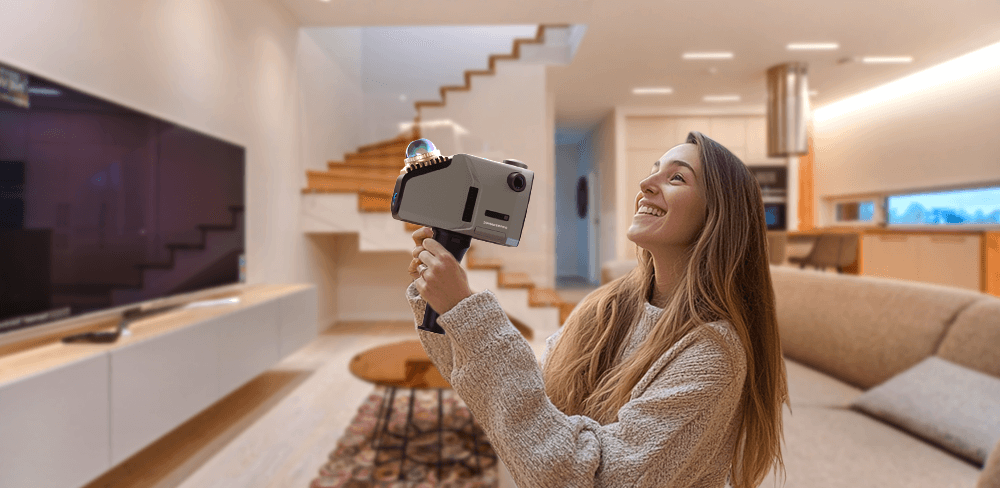

Dans les environnements où le scanner est en mouvement, comme lors d'une numérisation 3D portable ou mobile, l'IMU six axes de l'Eagle, composée d'un accéléromètre et d'un gyroscope trois axes, joue un rôle essentiel dans le suivi de la position et de l'orientation du scanner en temps réel. Cette fonctionnalité est essentielle pour générer des modèles 3D précis, notamment dans des environnements dynamiques comme les environnements extérieurs ou les chantiers de construction très fréquentés, où les conditions peuvent évoluer rapidement.

3. Numérisation de grandes scènes

Le scanner Eagle excelle dans la capture de scènes de grande taille avec un rayon de balayage unique allant jusqu'à 70 m et des vitesses de capture de mouvement allant jusqu'à 20 km/h. La capacité à numériser de vastes zones (150 m x 150 m) en moins de 5 minutes améliore considérablement l'efficacité du travail, permettant aux professionnels de couvrir de vastes terrains avec un minimum de temps d'arrêt. Cette capacité est particulièrement avantageuse dans des domaines comme la surveillance environnementale et l'urbanisme, où de grands ensembles de données sont souvent nécessaires.

4. Numérisation de scènes complexes

Grâce à la technologie SLAM (localisation et cartographie simultanées) , l'Eagle construit des modèles environnementaux détaillés et effectue un positionnement et un balayage en temps réel. Cette technologie garantit une modélisation précise d'espaces intérieurs complexes comportant de multiples itinéraires, niveaux et obstacles. L'IMU contribue à maintenir la précision du positionnement, garantissant ainsi des résultats de haute qualité dans des environnements difficiles.

5. Efficacité accrue

Le retour d'information en temps réel fourni par l'IMU réduit considérablement le temps nécessaire à la collecte et au traitement des données. Cette efficacité est particulièrement importante dans les secteurs où le temps est un facteur critique, comme la construction, la fabrication et les interventions d'urgence. Une acquisition de données plus rapide permet aux équipes de prendre des décisions plus rapides, améliorant ainsi les résultats des projets.

6. Polyvalence des applications

Les IMU sont extrêmement polyvalentes et s'adaptent à un large éventail d'applications de numérisation 3D, notamment la réalité virtuelle, la robotique et les véhicules autonomes. Leur capacité à assurer un suivi précis des mouvements les rend adaptées à la numérisation en intérieur comme en extérieur, élargissant ainsi leur champ d'application à différents domaines.

En résumé, une unité de mesure inertielle (IMU) est un composant essentiel de la technologie de numérisation 3D moderne, en particulier pour les systèmes avancés comme le scanner LiDAR Eagle. Sa capacité à améliorer la précision, à fournir des images de haute qualité et à suivre les mouvements en temps réel la rend indispensable dans de nombreuses applications. Face à la demande croissante de modèles 3D précis et performants, le rôle des IMU deviendra de plus en plus crucial. Cette évolution ouvrira la voie à des avancées dans des domaines allant de l'architecture et de l'ingénierie au divertissement et aux sciences de l'environnement. qu'est-ce qu'une IMU et son importance dans la numérisation 3D aide non seulement les professionnels à exploiter tout son potentiel, mais conduit également à de meilleurs résultats et innovations dans leurs secteurs respectifs.